Retrofitting Watermelon Buses to Improve Food Safety and Produce Handling (2022)

Retrofitting Watermelon Buses to Improve Food Safety and Produce Handling

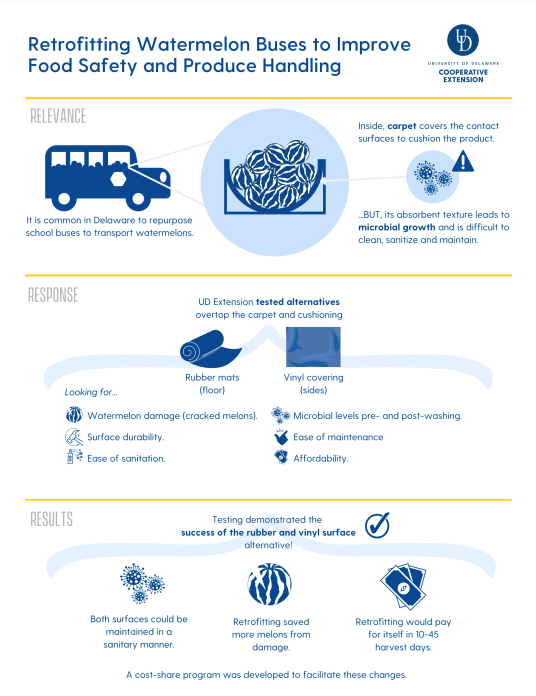

RELEVANCE

It is common in Delaware to repurpose school buses to transport watermelons after harvest. Carpet covers the contact surfaces to cushion the product during transport; however, its absorbent texture leads to microbial growth and is difficult to clean, sanitize and maintain. Further, competing priorities and limited farm resources make it difficult for growers to evaluate suitable alternatives.

RESPONSE

UD Extension identified a test alternative, fitting buses in Delaware and Maryland with rubber mats (floor) and vinyl coverings (sides) placed over the existing carpet or with padding underneath for cushioning. Agents compared these test buses to the unaltered carpeted busses in terms of:

Watermelon damage (cracked melons).

Surface durability.

Ease of sanitation.

Microbial levels pre- and post-washing.

Ease of maintenance

Affordability.

RESULTS

Visual assessment and regular use by participating farmers demonstrated the success and durability of the rubber and vinyl surfaces alternative. Microbial test results showed the rubber and vinyl surfaces could be maintained in a sanitary manner, with concentrations of E. coli consistently low both pre- and post-wash.

In terms of affordability, both proposed retrofit install strategies saved significantly more melons from damage compared to the carpeted buses:

Option one (vinyl over existing carpet):

Cost $399.

Saved 1,734 melons per season

Paid for itself in 10 harvest days.

Option two (padded vinyl)

Cost $2,371.

Saved 2,567 melons per season.

Paid for itself 45 harvest days.

Results were presented at the MarDel Watermelon Growers association annual educational meeting in February 2022 and the project was very favorably received. As a result of this project, a cost-share program was developed in cooperation with the Delaware Department of Agriculture with USDA funds to help watermelon growers to retrofit their own harvest buses.

PUBLIC VALUE STATEMENT

Retrofitting watermelon busses with rubber and vinyl (instead of traditional carpeting) offers a durable, affordable and easily-sanitized way of reducing watermelon damage during harvest.

FUNDING SOURCE / ACKNOWLEDGEMENTS

The project was shepherded by Jennifer Jones, Produce Safety Program Assistant, and supported by the staff and agents at UD Cooperative Extension and the Ann V. Carvel Research and Education Center. Information on microbial safety evaluations was used, courtesy of Dr. Angela Ferelli Gruber (University of Maryland). An unnamed industry partner provided the material and two designs to retrofit the buses.

Youtube: Out with the Old and In with A Liner

A University of Maryland and University of Delaware research study provided preliminary evidence for improving watermelon harvest buses with a change in the food contact surfaces. By using vinyl liners and rubber floor mats that can be cleaned and sanitized, microbial loads were reduced compared to the industry standard of used carpet. The liners and mats also provided cushioning that protected watermelon surfaces against damage during harvest.

A video about watermelon bus retrofitting.: youtube.com/watch?v=i0_duAlxgKg