Center for Food Sensory, Characterization, and Novel Processing (FSCNP)

A dynamic platform for innovation and collaboration in the food industry

About our center

The Food Sensory, Characterization, and Novel Processing (FSCN) Center is a dynamic platform connecting the University of Delaware College of Agriculture and Natural Resources (CANR) with researchers and industry stakeholders. Our partners include food processors and manufacturers, startups, distributors, retailers, and technology companies.

Housed within the UD Department of Animal and Food Sciences, the FSCN Center delivers professional services, such as sensory evaluations, food processing, product characterization, and pilot-plant production across a diverse range of food products. We are also committed to fostering innovation by supporting the development and adoption of new food processing and analysis technologies through internal and external collaborations.

Our center has state-of-the-art laboratory and pilot-plant scale processing equipment, comprehensive analytical instruments, and a highly skilled team. We continually upgrade our facilities and technology to enhance our capacity for multidisciplinary research and industry partnerships.

For collaboration opportunities or to learn more about our services, please contact our center director, Dr. Juzhong Tan, at jztan@udel.edu.

Key personnel

Principal Investigator

Dr. Juzhong Tan is an Assistant Professor in the Department of Animal and Food Sciences (ANFS) at the College of Agriculture and Natural Resources (CANR). With a background in food and electrical engineering, he leads multiple research projects focused on developing innovative processing and detection technologies for agricultural and food products. His work aims to enhance food safety, improve nutritional quality, and promote sustainability. His expertise includes food sensory, numerical simulations, extrusion, spray/freeze drying, postharvest processing, cold plasma, chocolate science, food analysis, AI, modeling, and electronics.

As the head of the Food Sensory, Characterization, and Novel Processing (FSCN) Center, Dr. Tan oversees a team that offers services and consultation in sensory evaluation, large-scale food processing, and comprehensive food analysis. The center collaborates with internal and external stakeholders, providing expertise and support for a wide range of food-related initiatives.

Dr. Tan is actively seeking new opportunities and collaborators for multidisciplinary research projects to drive impactful advancements in food science and technology.

Postdoc Associates

Dr. Hui Ru Tan

Expertise: Plant-based food processing, food analysis, and sensory

Contact: huirutan@udel.edu

Tan's research focuses on utilizing current and emerging food processing technologies to:

- Transform vegetable crops into sustainable food ingredients,

- Structure plant-based products, such as high-moisture meat analogs and texturized vegetable proteins, and

- Enhance the nutritional profile and physicochemical properties, and safety of plant-based ingredients.

Tan is proficient in pilot-scale processing techniques, including twin-screw extrusion and spray drying, and is skilled in food analytical methods such as chromatography and spectroscopy. She has authored multiple papers on extrusion-based technology for structuring meat analogs and developing analytical methods for food safety and authentication.

Dr. Ruogu Tang

Expertise: Organic and polymer chemistry, materials science and engineering

Contact: rgtang@udel.edu

With expertise in various analytical techniques, including FTIR, NMR, SEM, GC-MS, DSC, and hyperspectral imaging (HSI), Ruogu conducts in-depth characterization of material properties and structures to drive innovative research.

Currently, Tang’s research focuses on optimizing biochar-based materials for applications in soil enhancement, water filtration, and sustainable agriculture. By integrating interdisciplinary approaches and collaborating with industry and academic partners, this work aims to enhance resource efficiency, improve soil health, and develop eco-friendly solutions that address global sustainability challenges.

Facilities & Equipment

Food Processing Facilities

The FSCN Center features a newly renovated food pilot plant located in the O.A. Newton Building (314 Farm Ln, Newark, DE) on the UD Newark Farm.

This state-of-the-art facility is equipped with large-capacity processing equipment, including a twin-screw extruder, a spray dryer, two freeze dryers, a ball mill, multiple grain mills, a high-pressure homogenizer, and a complete chocolate processing unit.

The plant supports comprehensive product development for both food and animal feed, covering the entire process—from raw material preparation through processing to characterization and analysis.

Major processing equipment

Anton Paar Brabender TwinLab B-TSE-S 20/40 twin-screw extruder

1 kg/h to 20 kg/h throughput

20 mm screw diameter

2 x 40 Nm Max. Screw torque and 1200 rpm Max. screw speed

300 bar Max. processing pressure

With an automatic cutter, gravimetric feeder, modular cooling dies, and multiple dies.

Yamato DL410 Large Capacity Spray Dryer

Max water evaporation rate: approx. 3,000 ml/h

Temperature control range: 40°C - 300°C at inlet

Dry air flow rate: 0.3 - 1.0 m³/min

Two-way nozzle (Dia. of orifice: 0.7mm) Nozzle No.3 standard supply

Drying chamber: Ultra hard glass, I.D. 457 x 975(H) mm

Harvest Right Large Pharmaceutical Pro Freeze Dryer with Premier Vacuum Pump

8 trays and 10.25 sq ft. tray space

Ice capacity 6 liters

Height: 32.5", Width: 22.5", Length: 25.5"

Complete set of chocolate processing units, from bean to bar

One drum roast, 4 lb (1.7kg) capacity.

Two ALPHA12 Melangers, 12 lbs (5 kgs) capacity.

One CocoaT deluxe Winnower, 10-25kg (20-50lb) per hour throughput.

One CocoaT power Cracker, 60lbs (28 kgs) per hour throughput

One SAGA5 Temperer, 2-6 kg capacity with full programmed tempering process

Other processing equipment

One automatic ball mill, 0.4-4 L capacity

One Mockmill Lino Professional 200 Grain Mill

One Robot Coupe food processor

One high-pressure homogenizer

Two solid-state microwave generators

Sieve sets (8’’ and 12’’ diameters)

Food Sensory Facilities

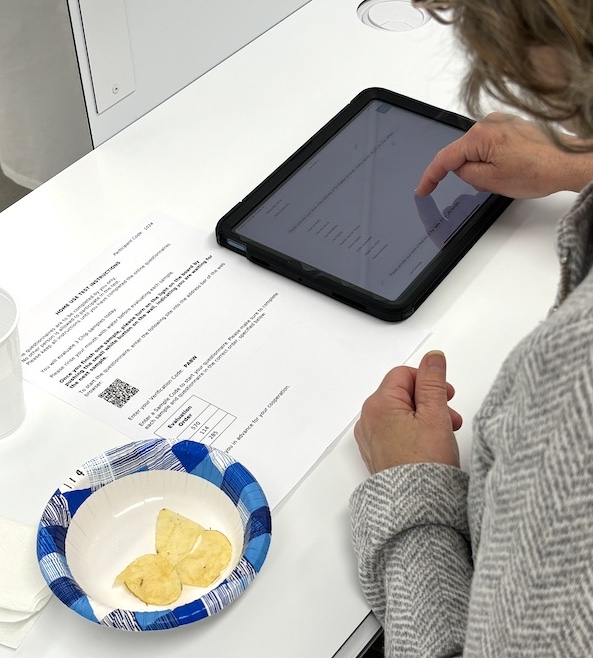

The sensory facilities are located in Townsend Hall, 529 S College Ave, toom, 120, Newark, Delaware, 19716. Recently renovated, the space includes a waiting area, a testing area with 10 individual booths, and a food-grade kitchen for sample preparation.

The facility can accommodate 30 to 50 panelists per sensory session (per day) for a range of acceptance and discrimination tests. Additionally, we have the capability to recruit and maintain a trained sensory panel for descriptive analysis. We utilize RedJade as our platform for developing questionnaires, conducting data analysis, and generating reports.

Food Characterization Facilities

FSCN Center collaboratively consists of five laboratories, including two food processing labs, one food analysis lab, one processing pilot plant, and one BSL II microbiology lab, in the Townsend Hall, Worrilow Hall, and O.A Newton Building. The PI of the center has access to UD's core facilities, such as the Advanced Materials Characterization Lab Core Facility and Mass Spectrometry Core Facility.

FSCN Center is equipped with and has access to a variety of both basic and state-of-the-art analytical equipment, providing comprehensive analytical analysis for the elemental, physicochemical, structural, techno-functional, and nutritional properties of food products.

Major analytical equipment

Anton Paar MCR 102e Modular Compact Rheometer with multiple probes and cells

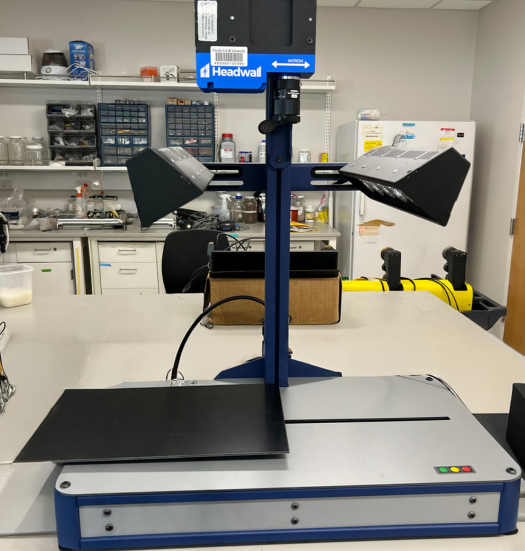

Headwall MV.C NIR Spectrometer (900-1700nm)

TA.XTplusC Texture Analyser with probes and 5kg-50 kg load cells

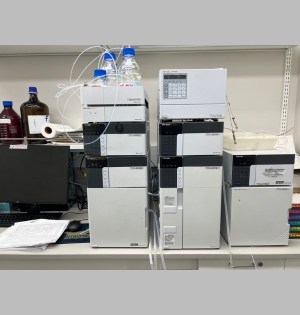

Shimadzu HPLC system

CEM Smart 6 Microwave + Infrared Moisture & Solids Analyzer and Rapid NMR Fat Analyzer

Other major analytical equipment with access

- Phillips Xpert Powder X-ray Diffractometer

- Rigaku Miniflex Powder X-ray Diffractometer

- Rigaku Ultima 4 Multipurpose X-ray Diffractometer

- Bruker D8 Multipurpose X-ray Diffractometer

- Phillip SAXS small angle Diffractometer

- T/A Instruments DSC, DTA, TGA, DMA, DTC

- Metrohm IC Pro Chromatograph

- Agilent HPLC 1260 /MS 6120

- Agilent Cary UV Vis Spectrometer

- Kaiser 785nm Raman Spectrometer

- Wyatt Dynamic Light Scattering

- Beckman Coulter LS13 320 Particle Analyzer

- Analsys NanoIR2

- Micromeritics Porosity Analyzer

- Agilent ICP/MS 7500

- Agilent AES 4100 Mass Spec.

Basic Analytical Equipment & Devices

UV-Vis spectrophotometers

NanoDrop spectrophotometers

qPCR

Fat analyzer/Soxhlet (6-unit device)

Moisture analyzer and water activity meter

Orion Star™ A325 portable pH/Conductivity meter

Colorimeters

Optical emission spectrometer

YSI MultiLab 4010-3W with complete kits and probes for ammonia, ammonium, nitrate/nitrite, fluoride, DO, chloride, potassium, sodium, copper, calcium, bromide, lead, and cadmium.

Muffle furnaces

Viscometers

Fee Structure

The fee for the services depends on the nature of the products, work, sample size, labor, hours, consumables, and other costs. For long-term and external collaborations, we typically develop one Memorandum of Understanding (MOU) for each collaborator to delineate the scope of work, fees, and timeline.

Contact

Juzhong Tan

Office location:

531 S. College Avenue

048 Townsend Hall

Newark, DE 19716