UD MakerGym

Photos by Evan Krape December 18, 2019

Novel makerspace boosts UD MakerNetwork for students, faculty, staff

The gymnasium where middle school students in Newark, Delaware, once took phys ed class will soon provide University of Delaware students with a different kind of work-out. They will get to exercise their creativity, their “mental muscles” if you will, in a one-of-a-kind makerspace — the UD MakerGym.

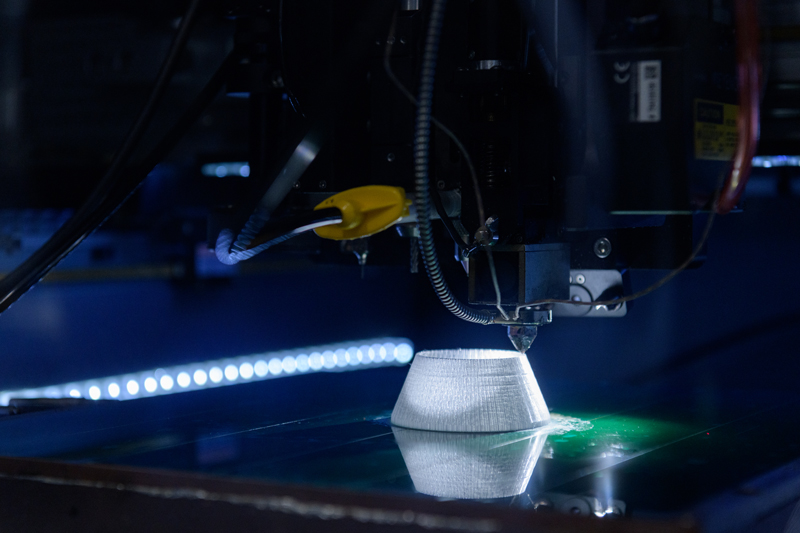

Located at the back of Pearson Hall, a former public school building the University purchased in 1981, you’ll now find the latest tools for developing projects ranging from integrating circuits into artwork, to prototyping a wearable medical device, creating hands-on lessons for elementary students and constructing sustainable housing. If you can think it, chances are you can build it here. Being readied are an array of state-of-the-art 3D printers, laser cutters, a water jet, a computer numerical control (CNC) router and mill, and industrial sewing machines, not to mention a 21st-century woodshop and an advanced manufacturing research center.

“The MakerGym is an amazing facility, where students, faculty and staff from across the University of Delaware will have the opportunity to make their ideas come to life,” UD President Dennis Assanis said at a November event celebrating the new space.

“There’s something absolutely thrilling about having an idea and then putting pieces together to make it a reality,” Assanis said. “The process of making something is an education in itself. You learn what works, and what doesn’t. And seeing your creation come to life just never gets old.”

The 6,700-square-foot MakerGym complements more than a dozen makerspaces across UD developing in such areas as wearable technology, astrophysics, graphic design and multimedia, education and physical mobility.

“This innovative and growing MakerNetwork at UD will fuel the work of a new generation of dreamers and doers,” Assanis said.

A boost for research

What sets UD’s MakerGym apart, besides its history as a gymnasium, is its focus on empowerment and collaboration. It is committed to open access for all campus makers — from all disciplines and experience levels — and will support academics, research and entrepreneurship, according to Mohsen Badiey, professor of electrical and computer engineering and newly appointed faculty director of the University’s Maker Initiative.

Badiey conceived the idea of a Maker Initiative while he was serving as acting dean of the College of Earth, Ocean and Environment a few years ago, envisioning a University-wide hub for creative collaboration, design, prototyping and entrepreneurship.

“Education is at a crossroads, with classrooms changing with digital integration,” Badiey said. “We want students to have experiences here that not just prepare them for future jobs, but inspire them to create the jobs of the future.”

Badiey partnered with Dan Freeman, director of UD’s Horn Entrepreneurship program — recently ranked one of the best in the nation — to develop a funding proposal to the Unidel Foundation, which awarded the team a $1.5 million grant to support the project.

“We see the MakerGym and Network as magnets for creative, innovative and entrepreneurial students,” Freeman said. “This is where students can manifest new ideas, create prototypes and iterate their product designs until they have the potential to deliver real, unique value in the marketplace.”

Pioneering research also will be done in the MakerGym, in the Advanced Manufacturing Technology Center. Behind the center’s walls, researchers will explore “additive” manufacturing—the process in which products are built by depositing, or “adding,” layer upon layer of material, such as plastic, metal, concrete or even living cells. According to center leader Mark Mirotznik, additive manufacturing is less costly, allows faster customization of products and produces less waste than traditional methods.

“UD is at the forefront in using this technology, which has the potential to revolutionize how products are created,” said Mirotznik, professor of electrical and computer engineering. As work in advanced manufacturing technology develops, he envisions a shared facility for cross-college collaborations, with plenty of synergy between research and education, particularly at the graduate level, to start.

Much of the center’s research will be supported by the federal government and by private industry and will complement work underway in UD’s internationally recognized Center for Composite Materials, where Mirotznik serves as associate director for digital design and additive manufacturing.

A vibrant MakerNetwork

Art Trembanis, associate professor of marine science and policy, has been working with faculty fellows across UD to integrate more maker courses into the UD curriculum. The fellows, representing fields ranging from fashion and apparel studies to plant and soil science, are developing undergraduate courses, some new and some reimagined. The first of these courses will use the MakerGym’s resources this coming spring semester.

“A gym is a place where you work out, you sweat, you improve your mind and body,” said Trembanis, who recently 3D printed a scaled-down version of a shipwreck his underwater robot located and mapped on the Pacific Ocean floor.

“Our message to makers across campus is that we want you to grow with us and sweat with us,” Trembanis said. “It’s good for your mental and physical well-being. It’s good for your soul.”

Stefanie Hansen, associate professor of theatre and a Maker Faculty Fellow, is looking forward to bringing her cosplay design class to the MakerGym this spring. She envisions her students creating fantastical costumes using 3D and laser printing to create designs that are uniquely their own.

“It’s very exciting,” Hansen said. “I don’t know how to use all the equipment myself yet, but we’ll learn together and I’m already looking forward to the students’ designs.”

Ashley Pigford, associate professor of graphic and interaction design, has been leading the maker team’s networking efforts, recently launching the MakerNetwork website to serve as a central source of information about spaces and makers across campus. The MakerNetwork allows all UD faculty, students and staff to turn their ideas into action by locating the facilities, equipment, training, people and opportunities they seek.

As co-director of UD’s Interaction Design (IxD) Lab, Pigford knows how makerspaces can change lives. Through his collaboration with doctors and therapists at Nemours/A.I. duPont Hospital for Children, he creates assistive technologies for children and adults with specific physical limitations, facilitating autonomous activities of daily living such as feeding oneself.

“The UD MakerNetwork encourages a campus-wide spirit of collaboration, innovation, entrepreneurship and inclusive excellence, which has already had a significant impact on the lives of the people I work with,” Pigford said. “I look forward to the amazing opportunities that will arise through more cross-campus connections.”

Jenni Buckley, associate professor of mechanical engineering, already sees benefits for the network. She co-directs the Engineering Design Studio, a nationally recognized makerspace that engages some 500 students in projects each year.

“With this great new resource in the MakerGym, we will not only be able to access advanced capabilities, but also serve the introductory maker,” Buckley said. She explained that students often contact her for training on a specific tool after a class is full. “This is where the MakerGym and its training resources will really help fill in.”

Work is underway to develop safety training and certifications that are transferable between makerspaces on campus. That’s one of the objectives of Brooks Twilley, the MakerGym’s operations manager.

Twilley oversees the technical staff who will train makers in the safe operation of equipment, provide design consultation to users and also keep all that high-tech gear humming along.

An engineer by profession, Twilley designed and operated manufacturing plants while working in industry. He later transitioned to a career in public education, as an award-winning engineering and computer science teacher in the Brandywine School District in Wilmington, where he developed integrated STEM labs and curricula.

Now at UD, he says he’s got the best job in the world, helping students from all backgrounds and disciplines bring their ideas to life, and in so doing, change the world.

“This is everyone’s sandbox,” Twilley said. Beginning this spring, he and his staff will be offering courses and workshops on design and fabrication for beginners and advanced users alike.

And the students can hardly wait to get in it.

Take Justin DiGiovanni, a junior from Wilmington, Delaware, who is majoring in mechanical engineering. He’s one of 16 student assistants who will be working at the MakerGym.

In high school, DiGiovanni was on a team at Concord High that helped design a patented system for ChristianaCare that uses magnetic technology to detect potentially dangerous objects hidden in textiles before they are sorted and cleaned in the hospital laundry.

“It showed me that you can create something that impacts someone’s life positively,” DiGiovanni said. “Now I just really want to help people.”

A place for exploration

For Badiey, the MakerGym’s opening is a dream realized.

“When I was a little boy, 4 or 5 years old, my dad would sit me on his lap and fix things,” Badiey said. “I learned not to be scared of opening equipment and dealing with it.” Badiey went on to become an expert in acoustics technology, to design and fabricate specialized instruments for detection and analysis of sound and vibration underwater.

“Through kindness and patience, he taught me to tinker with equipment and put things together,” Badiey said of his father, who recently passed away. “Likewise, we want the campus community to feel welcome and supported here, no matter what their level of experience, to come and explore their ideas.”

Starting spring semester 2020, the UD MakerGym will be open daily with extended evening hours. For more information, visit the MakerNetwork website.

Contact Us

Have a UDaily story idea?

Contact us at ocm@udel.edu

Members of the press

Contact us at 302-831-NEWS or visit the Media Relations website