Covid-19 Update

This page is dedicated to providing information about members of the UD MakerNetwork's ongoing effort to produce and deliver Personal Protective Equipment (PPE) to those who need it. A recent UDaily article provides a good overview of this effort.

Current PPE production projects include:

Face Shields, Cloth Face Masks and the "HensNest" Face Mask

Face Shields

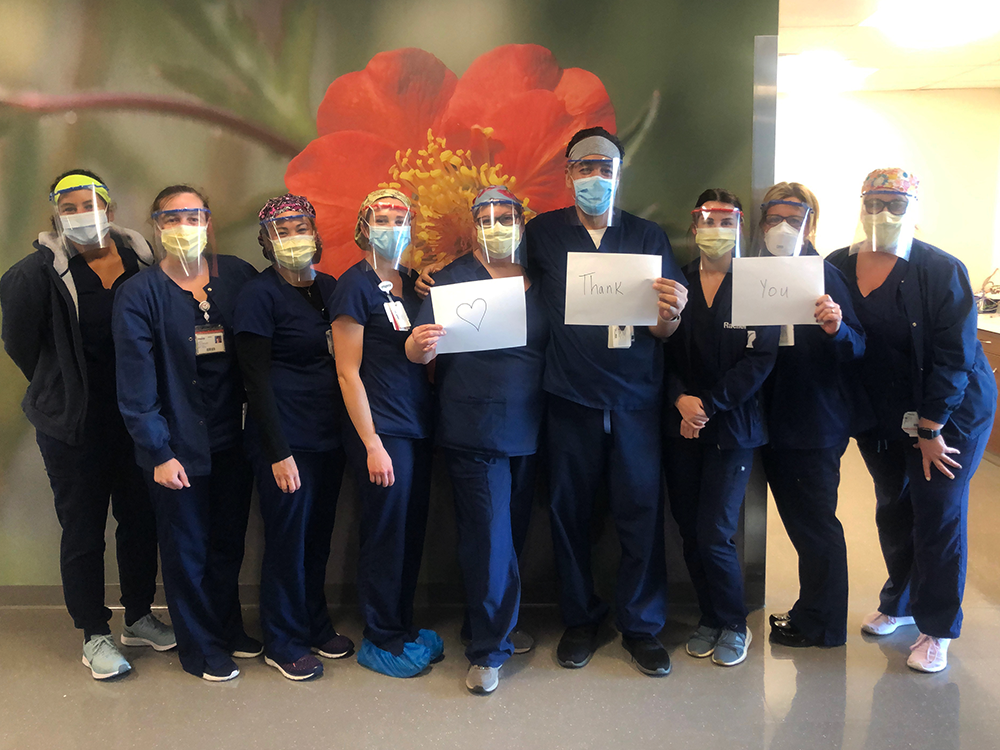

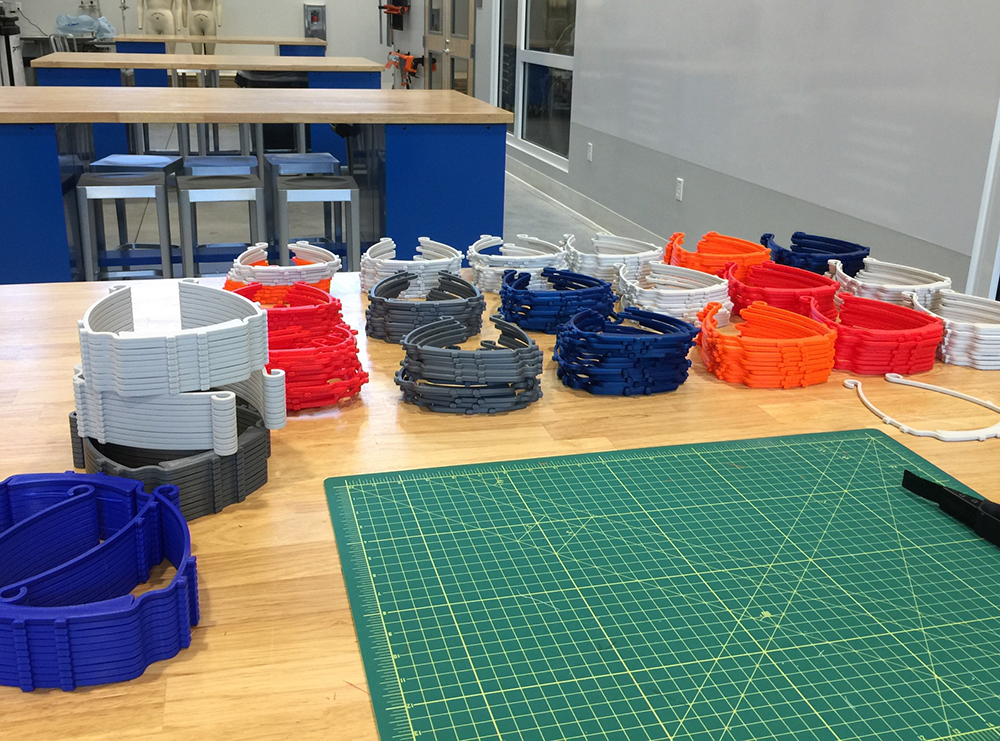

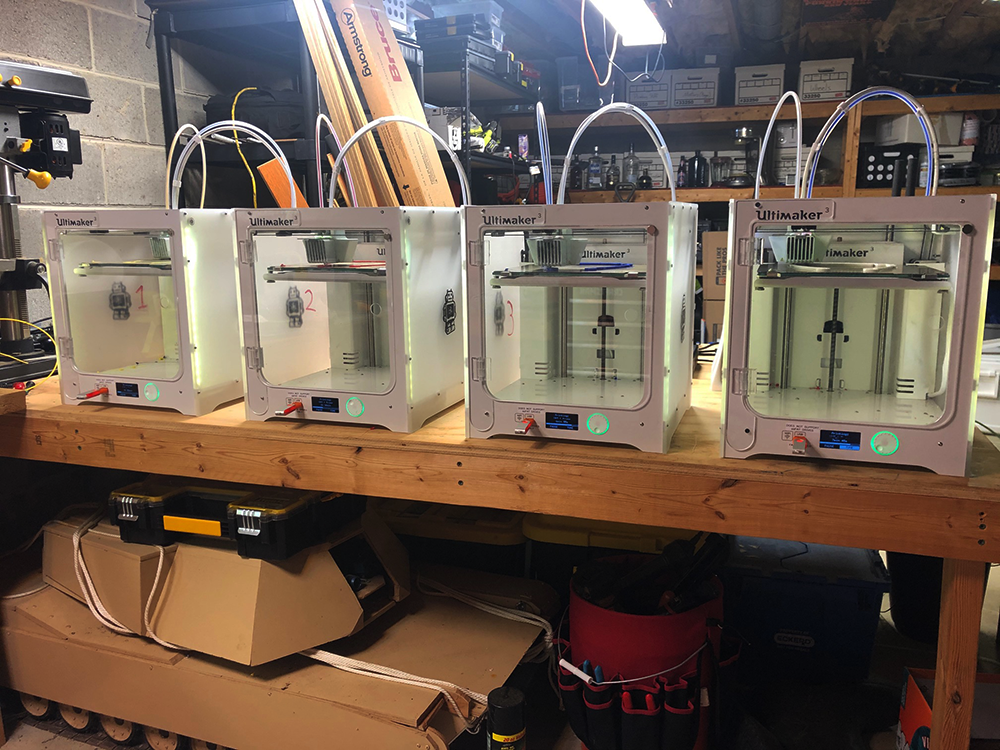

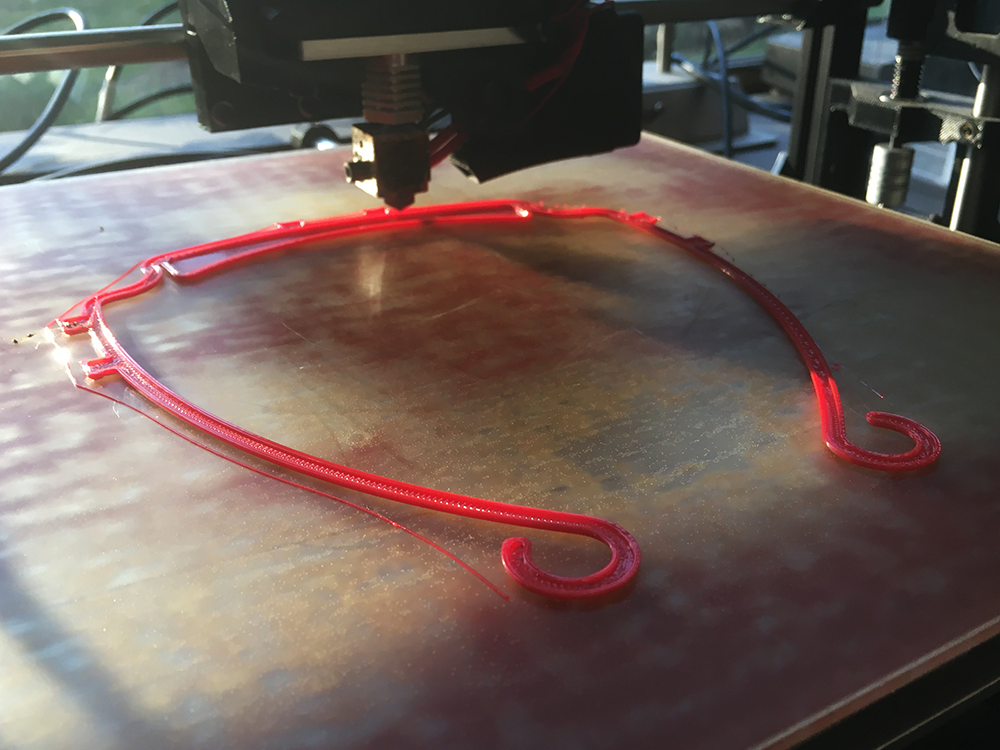

Members of the UD MakerNetwork are producing face shields for medical professionals in the area. In order to get these to those who need them as quickly as possible, MakerGym staff engaged with local doctors, nurses, dentists and medical device technicians to establish performance criteria. Medical staff were then presented several designs to consider. In total, a dozen or more local medical personnel had input on the design. Additionally, through the vetting process, Christiana Hospital produced a small batch of selected designs for trials. Their qualitative feedback, along with production considerations drove the design selection - Erik Cederberg of 3DVerkstan in Sweden. To date, eleven MakerNetwork contributors have collectively printed over 3,000 face shields for delivery to hospitals across Delaware, Pennsylvania and New Jersey.

Face Shield Production & Delivery Update

People Involved: (in addition to MakerGym staff) Zach Larimore, Tom Lum, Kun Fu, Ashley Pigford, Zach Swain, Michael Mackay, Rich McCann, Lance Winn, Adam Stager, Jessica Barth, Jia-Rey Chang and Art Trembanis.

Total Delivered:

- 600 to Veterans Hospitals in DE & NJ

- 400 to St. Francis Hospital, Wilmington, DE

- 800 to Beebe Hospital, Lewes, DE

- 400 to Nanticoke Hospital, Seaford, DE

- 1000 to Delaware Nursing Home Network

- 250 to Christiana Hospital, Newark, DE

- 50 to Chambersburg Hospital, Chambersburg, PA

- 200 to dentists in Newark, DE

- 230 to Inspira Medical Center, Mullica Hill, NJ

Cloth Face Masks

Cloth face mask production is happening across UD's Resident Ensemble Players, the Department of Fashion and Apparel Design and the Design for Health Innovation Lab. Having efficiently worked out logistics of sourcing material, cutting, stitching, delivery and production management, these teams deliver finished masks to UD's Environmental Health and Safety and Emergency Operations for relay to the Delaware Emergency Management Agency for distribution, and directly to local law enforcement.

Actors, staff from UD's Resident Ensemble Players hard at work making masks: youtube.com/watch?v=mU8pALupdYs

Cloth Face Mask Production & Delivery Update

People Involved:

Resident Ensemble Players Planning Teams: Kelly O’Rourke, Liz Baehr, Barb Hughes, Matt Mallard, Eileen Smitheimer, Becky Reed and Ellen Beltramo. There are, including these 7, 45 people supporting the efforts in a variety of different ways.

Department of Fashion and Apparel Studies Faculty: Adriana Gorea, Hye-Shin Kim, Katya Roelse & Kelly Cobb

Design for Health Innovation Lab Coordinator: Martha Hall

Total Delivered:

Resident Ensemble Players: ~1000

Department of Fashion and Apparel Studies: ~100

Design for Health Innovation Lab: ~500

HensNest Face Masks

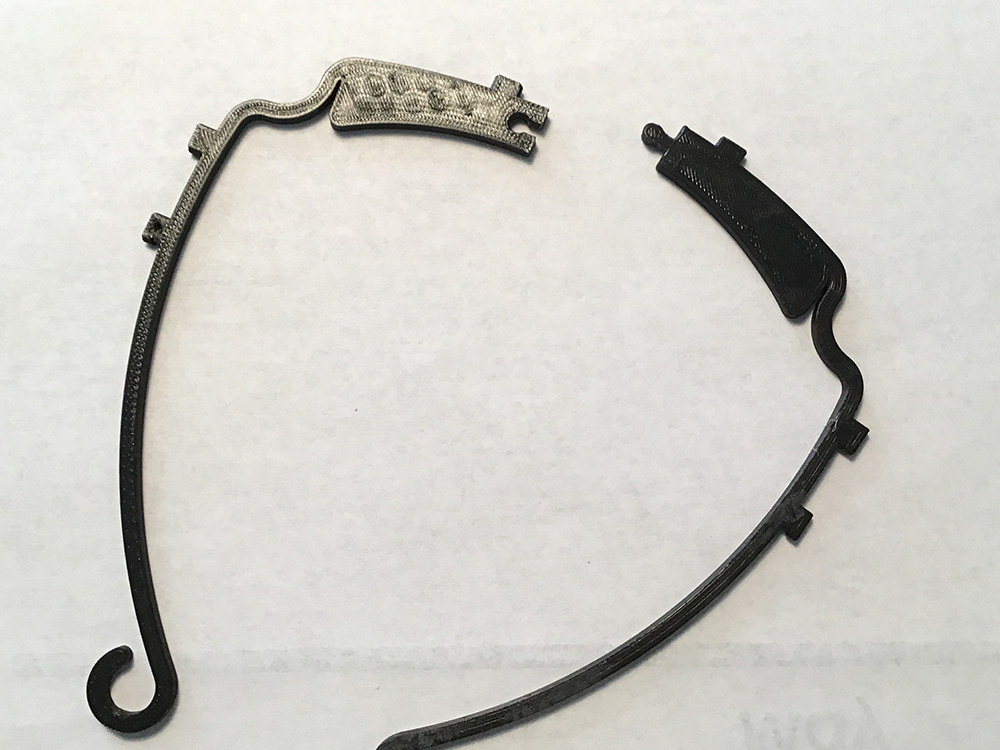

When a team of UD mechanical engineers evaluated existing 3D printed face masks, they found a few problems. Existing designs didn’t form a tight seal around the mouth and were made of material that needed to be custom molded and sealed—something many potential users don’t have the time and expertise for. So, the team designed a new and improved, easy-to-manufacture mask that includes a reusable 3D printed frame and allows the wearer to select their own filter piece for a custom fit.

How to assemble the HensNest face mask: youtube.com/watch?v=4QYMmyxlj_I

Now, the team is partnering with major manufacturers, including Celanese Corp and Stratasys Corp, to rapidly injection mold units in their local areas and in Delaware.

Want your own mask? Download the design files from GrabCAD or the NIH 3D Print Exchange so you can print a mask. Complete assembly instructions are available here. Fill out this form if you’d like us to send you a completed mask.

More Information is on the Department of Mechanical Engineering's webite.

HensNest Production Update

People Involved:

Whitney Sample, Co-Director of The Design Studio, Studio teaching assistant Arnav Prasad, associate professor Jenni Buckley, Engineering Alumni Distinguished Professor Ajay Prasad, Dr. Lisa Lattanza, Chair of the Department of Orthopaedic Surgery at Yale University and Co-Founder (with Prof. Buckley) of The Perry Initiative, Mike Gladle, Director of Environmental Health and Safety.