Yeast in space

Photos by Evan Krape and courtesy of NASA April 12, 2023

UD Engineering’s Mark Blenner is part of a research project to improve biomanufacturing in space

As part of its “Moon to Mars” initiative, NASA plans to send humans farther into space than ever before. But there are several challenges that must be solved before long-distance, years-long space missions can take place, from protecting passengers from radiation to the psychological impacts of long-term isolation.

Addressing one facet of those challenges, by developing a reliable source of essential nutrients, medicines and vitamins, are researchers working on B-SURE (Biomanufacturing: Survival, Utility and Reliability beyond Earth). B-SURE is a research program funded by a $2.8 million grant from the Defense Advanced Research Projects Agency (DARPA) that will bioengineer microbes for experiments on the International Space Station (ISS).

The project is led by University of Florida’s Amor Menezes in collaboration with researchers from University of California, Berkeley, the University of Delaware, the NASA Ames Research Center and Rhodium Scientific, a company that facilitates space-based scientific experiments.

At UD, B-SURE co-principal investigator Mark Blenner, associate professor in the College of Engineering’s Department of Chemical and Biomolecular Engineering, and his group have bioengineered yeast strains for the project’s first of two space flight experiments. The samples were loaded onto the SpaceX Dragon that launched from NASA’s Kennedy Space Center on March 14, 2023, and are currently on the International Space Station.

The benefits of biomanufacturing

Blenner’s Cellular Engineering and Applied Synthetic Biology Lab bioengineers microorganisms to address challenges in sustainability, human health, and national defense. He has also used his synthetic biology expertise for experiments in space — through early career awards and a sabbatical with NASA, Blenner previously engineered yeast to use waste products, like the carbon dioxide exhaled by astronauts, as a carbon source for synthesizing vitamins and nutrients.

While working with NASA and the Defense Threat Reduction Agency (DTRA), Blenner collaborated with Rhodium Scientific, which resulted in sending his lab’s engineered yeast strains to the ISS on the Northrop Grumman commercial resupply-14 mission to see how well they performed under space flight conditions. Now, thanks to this DARPA grant, Blenner and other members of the B-SURE team will work on improving the capabilities of yeast biomanufacturing in zero-gravity environments.

“Biotechnology is increasingly appreciated as a flexible manufacturing technology that's well suited for meeting the needs of people in deep space exploration,” Blenner said about the role of biomanufacturing in space missions. “Getting to Mars is a months-long mission, and there are important medicines and vitamins that will not survive that trip. Biomanufacturing is a promising solution because of the ability to take a microorganism and program them through genetic engineering to make a wide range of different things.”

Defying (micro)gravity

One of the challenges of biomanufacturing in space is the impact of microgravity on yeast, Blenner said. “Having low-to-no gravity changes a lot of the fluid dynamics in the bioreactors, and that can have a really big effect on how the cells behave,” he said.

But Blenner and his team are ready to address that challenge, thanks to their previous experience with space biomanufacturing experiments and their partnership with Rhodium. “The project is only 18 months, but we are realistically planning two space flight experiments in that time. Our ability to execute at that speed is going to be a distinguishing factor, and that's an expertise that Rhodium brings to the project,” Blenner said.

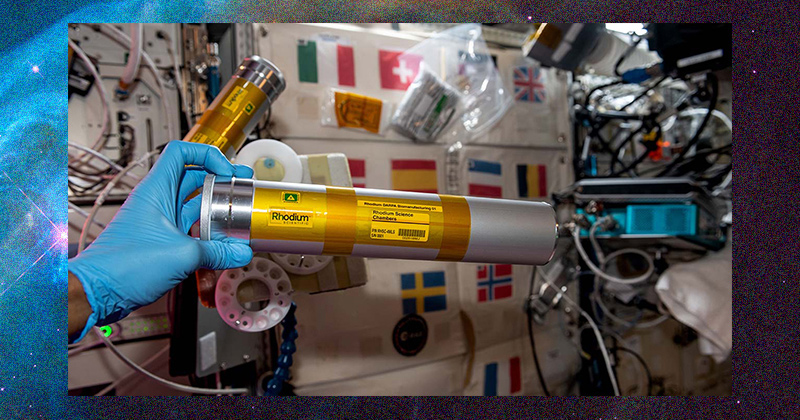

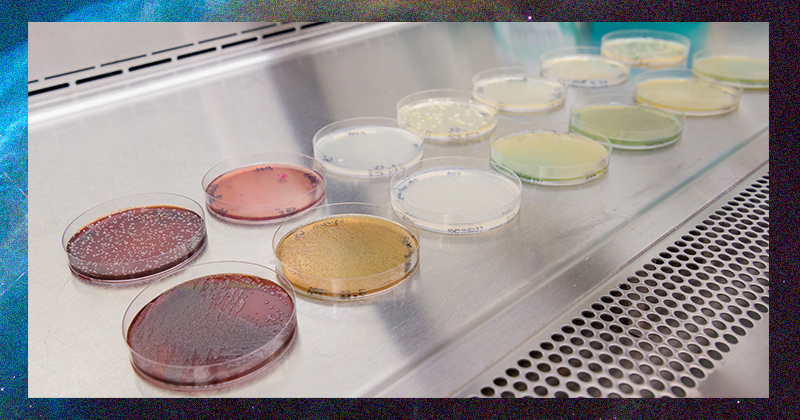

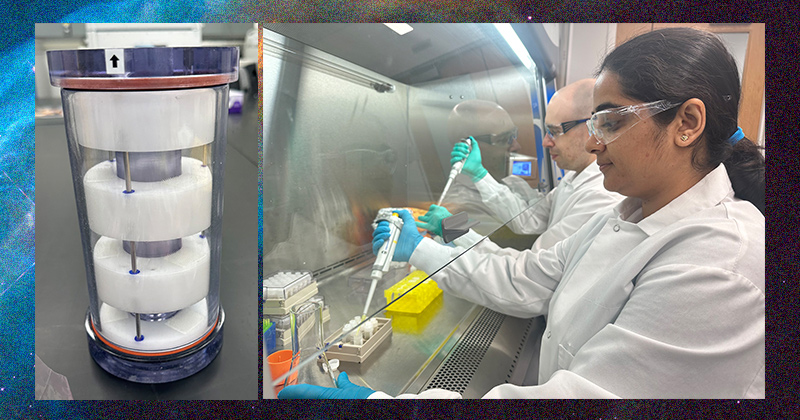

At the start of the B-SURE project, Blenner lab members Mike Spagnuolo, a recent doctoral graduate, and postdoc Richa Guleria engineered several different yeast strains that could synthesize products like vitamins, medicines and green fluorescent protein and confirmed that the yeast were able to maintain growth and production levels when they are housed in the specialized vessels required for space flight.

For the experiments that the astronauts will conduct on board, Spagnuolo explained, the astronauts will thaw the frozen yeast samples, load them into dedicated equipment aboard the ISS, then return the samples to the freezer after the growth experiment is complete.

Once the samples are back on Earth, the researchers will conduct transcriptomic analysis, a tool for looking at the expression of thousands of genes in a single sample. Gene expression patterns in the samples taken to the ISS will be compared with ones that were grown on Earth to determine how the yeast react to space flight conditions.

“One of the things we are doing on ISS is growing yeast and bacteria at different gravity conditions. Then, we’ll do ground analog experiments using HARVs (High Aspect Ratio Vessels) that attempt to mimic microgravity conditions,” Blenner said. “We expect there to still be differences between simulated and actual microgravity, which supports the need to identify better hardware to mimic variable gravity and better models to relate ground experimental data to how these strains would perform in space.”

By using changes in gene expression patterns to understand how the yeast respond to stress, the goal for the next phase of the project will be to modify specific genes in a way that will help the cells maximize product output even under those stressful spaceflight conditions.

“When we are growing these microbes under different conditions, there is a change in gene expression patterns, and by using transcriptomics we can find these differences,” Guleria said of the use of transcriptomics. “Then, we can focus on a specific set of genes and find out how these genes are involved in specific changes, such as modifying the growth rate or impacting production, and we can fine tune those genome integration networks using metabolic and genomic engineering approaches.”

Peak biomanufacturing performance

After modifying key stress response genes, the researchers will take what they learned and complete a second space flight, planned for 2024, to see how their new and improved strains perform in space. “We can then implement the genetic circuit that, in response to the spaceflight condition, will keep those expression levels high,” Blenner said.

While there are several unknowns that the researchers won’t have a good handle on until the first round of transcriptomics data are available, the researchers are already familiar with strategies to keep these engineered cells at peak performance even in suboptimal conditions.

“Part of the work is that you don't know what the problems are going to be, and so we're trying to create as resilient a system as possible for the experiment,” Spagnuolo said. “Hopefully by the end of the project we will know more about how to prepare these samples to be more resilient in space.”

Said Blenner, “It’s going to be difficult to understand all of the detrimental effects of microgravity on how the cells respond, but our lab’s biggest contribution is that we use synthetic biology tools that allow us to make larger numbers and relatively quick changes to the genomes of these cells. So being able to scale up the synthetic biology part of this, to make more strains faster, is one way that we're going to solve this problem.”

While the researchers are waiting for the yeast samples to return from the ISS, there is no sense of idleness in the lab. The timelines are short, especially with two planned space missions in an 18-month period, and the researchers are ready to put their skills and expertise to good use in order to get these yeast to thrive in microgravity.

Spagnuolo said he is particularly interested in the second stage of the project, where they will be able to see if the genetic changes they make after the first flight can “mitigate those negative effects and allow it to better tolerate, grow and make products in a reduced gravity environment.”

“I hope we'll have shown that we can improve the performance of these strains in microgravity,” added Blenner. “Because if we can do something, that means we can probably do more with time and resources to continue to improve how the strains perform in space.”

Contact Us

Have a UDaily story idea?

Contact us at ocm@udel.edu

Members of the press

Contact us at 302-831-NEWS or visit the Media Relations website