Additive manufacturing

Graphic illustrations by Jeffrey C. Chase December 14, 2020

3D-printing technology at UD enables novel lenses for wireless communications

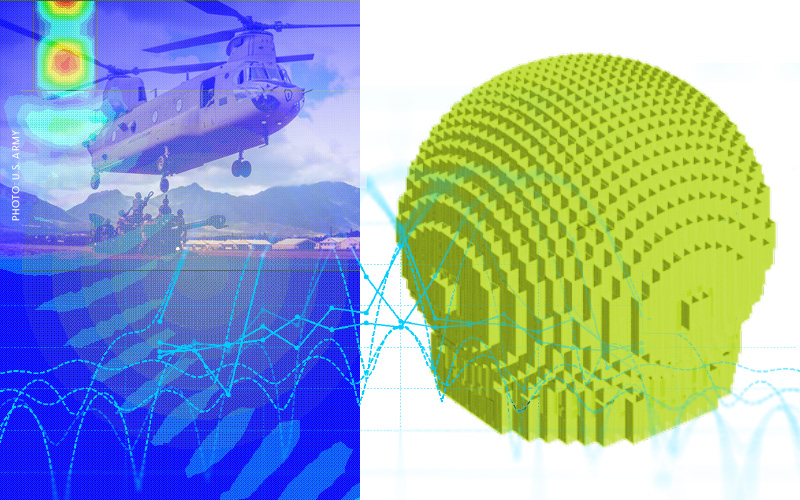

University of Delaware Professor Mark Mirotznik and others in UD’s Additive Manufacturing Technology Center are developing novel device lenses for wireless communications that could usher in a new wave of capabilities.

These are not optical lenses, though. These lenses operate at frequencies where your mobile phone and 5G technology work. They are plastic parts, called graded index lenses, with the ability to bend communications signals.

This ability to bend a communication beam is a sought-after characteristic in wireless communications, one that has challenged scientists and engineers. According to Mirotznik, a professor of electrical and computer engineering, people have considered ways to make graded lenses for this purpose before but found it difficult to fabricate them.

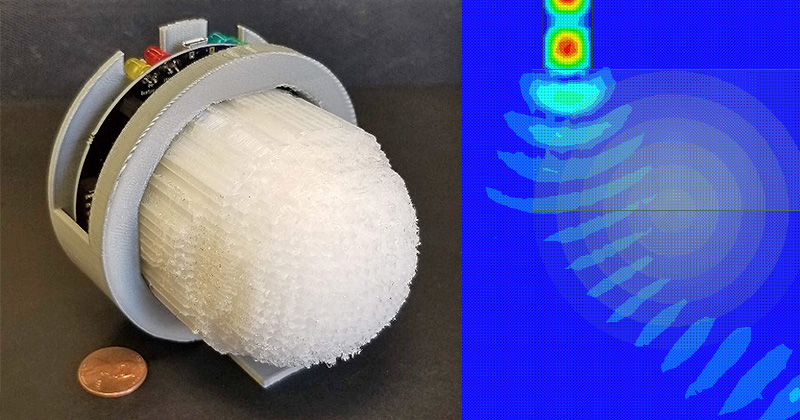

Now, Mirotznik and Soumitra Biswas, who earned his doctoral degree in electrical engineering at UD in 2019 and is now a research scientist with Envistacom, devised a way to make a novel lens using additive manufacturing, a group of technologies designed to build 3D objects by laying down layer after layer of material.

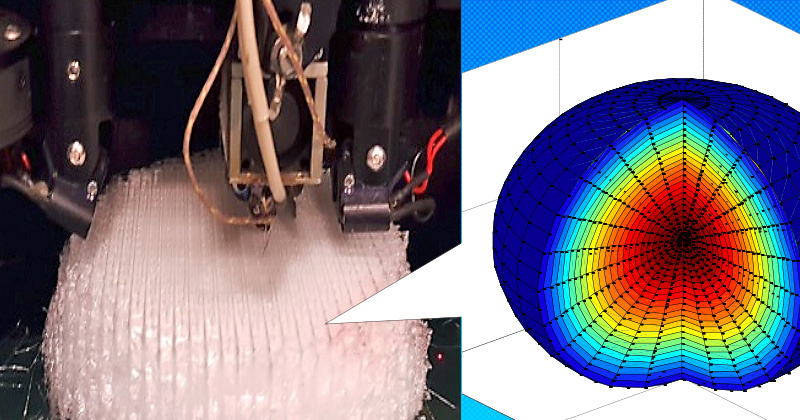

Additive manufacturing is less costly, allows faster customization of products and produces less waste than traditional methods. The research team’s 3D-printing method enables them to vary the plastic on an exceedingly small scale, creating intricate geometries that make it possible to change material properties at each location on the lens. This allows them to create 3D structures in patterns that place desired electromagnetic properties at the exact right location.

The team also designed the lens to have a flat surface on the bottom, which allows the researchers to add functional features, such as electronics, sensors and batteries, so that the lens can be adapted into devices or integrated into applications like cell phone technology that have tiny little antennas on them.

The Army is interested in the lens technology for its capabilities in direction-finding or situational awareness.

“This lens is a very inexpensive, effective way of steering communication signals in a particular direction,” said Mirotznik. “It will be particularly useful with 5G technologies that operate using high-frequency millimeter waves.”

For example, say soldiers want to know if a foe’s communications or radar system is trying to find them. According to Mirotznik, the UD-developed system can detect that you are being looked at and from what direction.

Mirotznik and Biswas, who reported their progress in an article published in Nature Scientific Reports, both said this lens technology also will be an advantage as 5G technology becomes more widely distributed.

Today’s consumers want 5G because it will give them faster communications, for things like video streaming or gaming, by accessing a wider swath of the wireless spectrum. But 5G is used in the internet of things, too, where smart devices are able to communicate with each other and to collect and exchange data, such as with self-driving cars.

Mirotznik expects we will see cities where every block contains many integrated sensor technologies—on buildings, light posts, stop signs—that communicate with our cars and gather information on things like a vehicle’s location and speed.

“We think our lens might have applications for those sorts of ‘edge-of-the network’ kind of things because they are inexpensive, yet really robust. You can set them at the edge of the network and communicate with cars or use it for radar obstacle avoidance,” said Mirotznik.

To transition the technology to real-world applications, such as those mentioned, Mirotznik’s team is working with DeLUX Advanced Manufacturing, a local startup company he co-founded with UD alumni Zach Larimore, Paul Parsons and Austin Good. Based in UD’s STAR Campus incubator, the company specializes in using additive manufacturing to develop products for defense, telecom and pharmaceutical applications.

Additive manufacturing expertise

The current work, meanwhile, is a collaborative project with the U.S. Army that is funded by the Department of Defense. It builds on UD’s existing expertise in additive manufacturing and sensor technology development.

UD’s Advanced Manufacturing Technology Center is situated adjacent to UD’s MakerGym, which opened in February 2020. While a majority of additive manufacturing revolves around building structural things out of metal or plastic that can replace other structural materials, the UD center focuses on integrating electronics and energy systems into the additive manufacturing process.

The uses for these types of smart materials are wide ranging and, because the technology is programmed remotely, it doesn’t require a human presence to set the works in motion.

“We’re fabricating these systems without ever touching them, things like fully-electronic radar systems, communication systems and the like. This lab has turned into a boom for us,” said Mirotznik.

Over the long term, Mirotznik said the Army would like to see the researchers create the capability to 3D print a fully automated robot that can usher itself off the conveyor belt automatically and push a button on its way out to have the machinery start fabricating the next one.

It’s a tall order, and UD researchers haven’t succeeded just yet. They are, however, making progress. For example, they have been able to 3D print items that can move themselves from what is called the build plate, meaning where they get made, to a nearby table.

Involving both graduate and undergraduate students is an important part of the work, said Mirotznik, one that fosters experiential learning opportunities for the students, while allowing students to contribute their creative ideas. Currently, there are a dozen graduate students and six undergraduate students involved in various projects in the center.

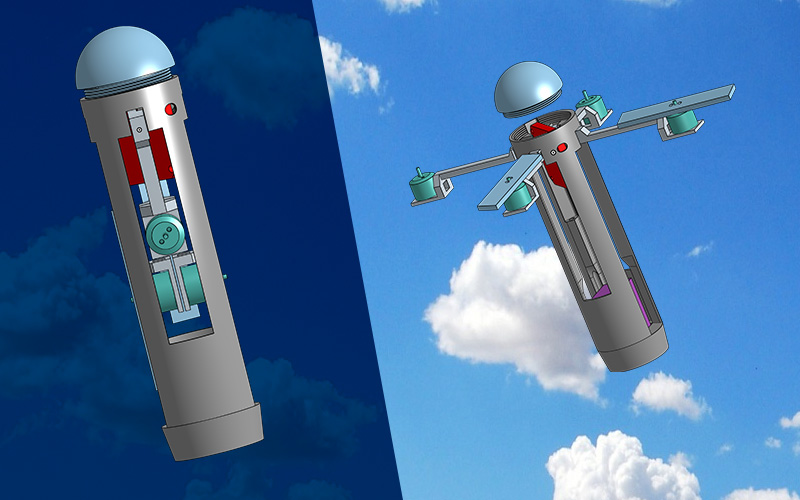

For instance, junior Evan Battaglia is working on technology for making 3D-printed quadcopters equipped with integrated electronics and sensors that can fold into a tiny package. Once airborne, the quadcopter can fly over an area of concern and send back images or data, such as whether there are chemical hazards ahead, to inform what the soldiers do next. The drone device is compatible with other systems, so it won’t add extra weight to what soldiers already carry.

Battaglia developed the quadcopter technology from his home in New Jersey during the pandemic. Mirotznik provided a 3D printer and some basic equipment, and Battaglia designed, 3D printed and tested a prototype device over the summer, integrating cameras into the quadcopter so that it could send video in real time.

“It demonstrates that even though students are at home and working via distance learning, they are still integrated with us and our research. They are still doing cool things,” Mirotznik said.

The novel equipment the University has acquired over the years in this area serves to bolster this type of student creativity. One machine, which Mirotznik called “the Swiss Army knife of additive manufacturing” contains six different 3D-printing tools integrated into the same setup that allows researchers to completely fabricate complicated electronic devices without ever having to touch the part.

New to UD this fall is a multitool 3D printer made by nScrypt Inc. that will allow researchers to create and print layered structures with six axes of control, rather than the traditional three-pronged x-y-z printers. With this instrument, UD students will be able to set the printhead at any angle to print custom plastics, inks, pick-and-place electronics and myriad other inventions their imaginations can create. Currently, there are only three of these machines in the world. UD is the only university to have one.

These advanced capabilities also position UD to help others, including the military, achieve new gains in additive manufacturing.

As 3D printers are becoming ubiquitous for many applications, Mirotznik envisions the military having on-demand manufacturing, by locating these multi-material, multi-tool printers in places where it is logistically difficult to replace items quickly. This includes locations such as foreign operating bases or even on the International Space Station. It would allow the military to print new devices, electronics or sensors on site. If something breaks, they just make another one.

With few other institutions or facilities working in this area, UD’s Additive Manufacturing Research Center stands ready to help.

“It is a pretty small community. UD has a foothold in this,” said Mirotznik.

Contact Us

Have a UDaily story idea?

Contact us at ocm@udel.edu

Members of the press

Contact us at 302-831-NEWS or visit the Media Relations website