Advanced 3D “bioprinters” help researchers find new disease treatments: youtube.com/watch?v=Sct2yhwYlLk

High-throughput innovation

Photos by Evan Krape | Photo illustration and video by Jeffrey C. Chase January 05, 2024

Researchers in the lab of April Kloxin are using an advanced ‘bioprinter’ to help them study and test new therapeutics

The ability and ease of growing cells in a laboratory setting has been a key factor of recent progress in fields such as biology, agriculture and medicine, enabling researchers to more easily study how different chemicals or environmental cues impact a cell’s growth and development.

To make further progress, researchers are now exploring cell culture alternatives that are more representative of how tissues and organs work. One such alternative is 3D cell cultures, which have the advantage of being more physiologically relevant but come with their own logistical and technical challenges that have limited their widespread adoption.

At the University of Delaware, researchers in the lab of April Kloxin are working at the forefront of this field by engineering unique materials and 3D cell culture and disease models. Now, thanks to a partnership with Inventia Life Science, the group has access to an advanced “bioprinter” that can help translate its 3D cell cultures into higher-throughput formats that can make research on finding new disease treatments even faster.

Engineering, materials and biology

Kloxin, the Thomas and Kipp Gutshall Development Professor in the College of Engineering with joint appointments in the departments of Chemical and Biomolecular Engineering and Materials Science and Engineering, explained that her group works “at the interface between engineering, materials, and biology” and is interested in studying how a cell’s environment influences things like injury, aging and disease progression. Their long-term goal is to use these insights to find better tissue repair strategies and disease treatments.

To do this research, the group specializes in building 3D disease models “from the ground up” by taking individual cellular building blocks (like proteins and polymers) and connecting each component so they best mimic how tissues actually work. Kloxin said that these models can provide complementary insights to data collected from traditional preclinical drug testing platforms such as 2D cell cultures or animal models.

“We see these engineered multi-dimensional model systems as a more potentially relevant environment than a traditional tissue culture dish, one that could enable us to ask more complex research questions,” she said.

Inkjet-based biology

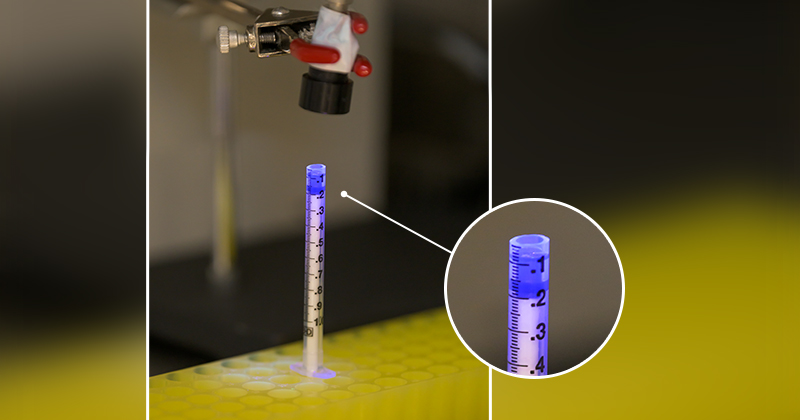

Now, the Kloxin lab will be able to take its current 3D cell culture models even further thanks to a partnership with Inventia Life Science, an industry leader in polymeric materials design that develops cell models and testing platforms. Through this partnership, the researchers now have access to a “bioprinter,” the RASTRUM™ 3D Cell Culture Platform, that is currently located in the Kloxin lab in the Ammon Pinizzotto Biopharmaceutical Innovation Center on UD’s Science, Technology and Advanced Research (STAR) Campus.

Bioprinting is the process of fabricating tissue- or organ-like structures with materials and living cells. Using the same principles as an inkjet printer, the RASTRUM™ allows researchers to combine “bio-inks” with cultivated cells and customizable mixtures of extracellular matrix (ECM for short, which are made of proteins and other molecules that provide structure to surrounding cells), place them into a cartridge, and then “print” 3D cell cultures directly onto a multiwell cell culture plate.

For Kloxin, having access to the RASTRUM™ is an opportunity for her lab to translate its 3D disease models into a format that makes it easier to screen potential therapeutics in a much faster, more high-throughput manner.

“Since we’ve already established the design rules, we can now print our cells into a well plate format that really allows for rapid drug screening,” she said. “We see this partnership as a great way to increase access, make science more reproducible and rigorous, and to be able to translate our disease model systems.”

Spurring new research, collaborations

Several researchers in the Kloxin Lab are already or will soon be using the bioprinter to further their work. Bree Huntington, a doctoral student who is co-advised by Eric Furst, is studying engineered fibroblasts to understand the process of quiescence vs. activation in these cells, as well as how their interactions with different matrices promote healthier, more effective wound healing.

Huntington said that the Inventia platform will allow her to screen a larger number of matrix interactions and more quickly see how environmental changes correlate to mechanical properties and responses of the cells.

“I’ll be looking at changes in the material mechanics between a quiescent versus an activated cell to see if we can correlate them,” Huntington said.

Jodi Graf, a doctoral student co-advised by Cathy Fromen, studies a type of immune cell called a macrophage and how these cells impact lung diseases such as COPD. She is currently using the bioprinter to see how different matrix compositions affect macrophage phenotype and function.

“It definitely makes my workflow easier. The RASTRUM™ is consistent, well-defined, and high throughput, making it faster and easier than if we were to make each gel by hand,” Graf said.

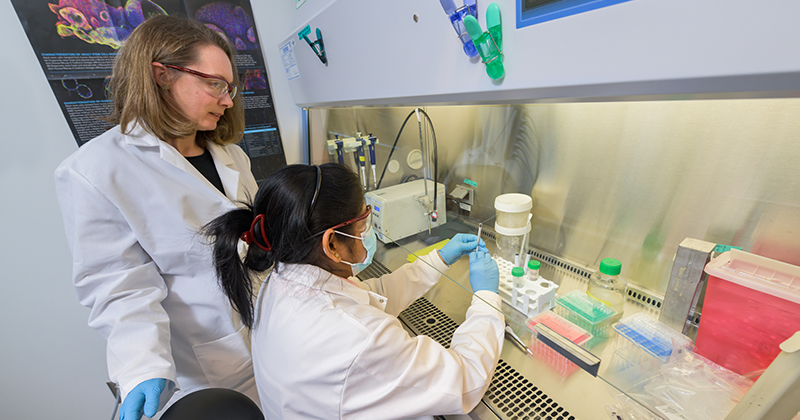

Lina Pradhan is a research associate who has been working in the Kloxin Lab for six years. Her projects include mechanisms of breast cancer recurrence and studying the disease mechanism of lung fibrosis. Before their lab had access to the RASTRUM™, certain aspects of her work had to be done manually, she said. Now, not only are portions of their workflow faster to complete, the bioprinter also enables new avenues of research, such as co-culture experiments using lung epithelial cells in combination with fibroblasts or macrophages.

“For certain experiments, it can minimize the time you need to spend in the lab. And with preliminary studies you can more quickly figure out what parameters will work best for future, more challenging experiments and projects,” Pradhan said about the bioprinter’s benefits.

In addition to research achievements, Kloxin hopes the RASTRUM™ can spur additional partnerships and collaborations, especially thanks to its location on STAR Campus.

“My hope is that, as we demonstrate the utility of the platform, there will be the opportunities to work with others at UD who are interested in 3-dimensional cell culture,” Kloxin said.

In addition to their existing partnership, this ongoing collaboration will be further enabled thanks to additional funding from the Delaware Biotechnology Institute Center for Advanced Technology (CAT) grants program. For this project, principal investigator Kloxin, co-PI Fromen, and industrial partner Inventia will be focused on creating 3D cell culture models for evaluating therapies for difficult-to-treat types of cancers like triple negative breast cancer.

Working at new scales

"Inventia is committed to establishing better in vitro models for disease research, and one of the main reasons I chose Delaware for Inventia US was its proximity to University of Delaware and its renowned research programs in biomaterials, life science, and engineering,” said Dwayne Dexter, director of sales and operations for Inventia US, which recently set up an office at the Experimental Station in Wilmington. “Working with April Kloxin and her colleagues, we look to support leading edge new approaches to drug discovery and create more translatable models which bridge the gap between in vitro preclinical studies and human disease."

From new avenues of research to higher-throughput drug testing capabilities, there’s a lot of exciting possibilities using the RASTRUM™, Kloxin said.

“Before, we were working at scales where we could do hypothesis testing and evaluation of specific therapeutics, but we were bottlenecked by not being able to prepare samples at scales for screening an array of drugs,” she said. “Now, we have the opportunity to translate our model systems for broader therapeutic screening. Then, we can make these models even more accessible for potential partners.”

Contact Us

Have a UDaily story idea?

Contact us at ocm@udel.edu

Members of the press

Contact us at 302-831-NEWS or visit the Media Relations website