Pulmonary engineering

Photos by Evan Krape | Photo illustration by Joy Smoker March 17, 2023

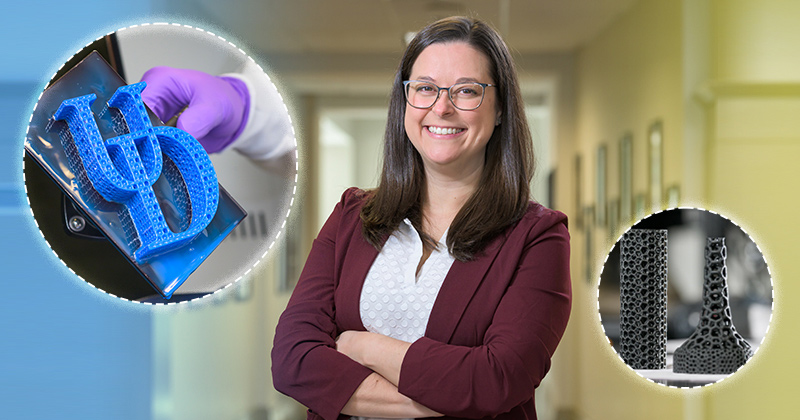

UD Engineering’s Catherine Fromen received an NSF CAREER award to study 3D-printed lattices for testing inhaled medicines

What organ has the surface area of a tennis court, expands and contracts 17,000 times every day, and contains passageways that range from centimeter-sized tubes to vessels that are narrower than the width of a human hair?

The answer is our lungs, an incredible organ system that delivers oxygen and removes carbon dioxide from the blood. But the features that make the respiratory system so incredible also make it incredibly hard to study, a challenge for researchers who are working on inhaled drugs or vaccines and need reliable ways to test how well new therapeutics work.

Focusing on ways to study and treat diseases in this crucial yet complex organ system is Catherine Fromen, assistant professor in the Department of Chemical and Biomolecular Engineering in the University of Delaware’s College of Engineering. Now, thanks to funding from the National Science Foundation, her group will expand their work on aerosol transport in a new model of the human lung, with the goal of improving preclinical testing for inhaled therapeutics.

Fromen’s lab members use tools from engineering to study and develop new therapies that target the lung. Her lab’s portfolio includes research on nano-scale medicines, how inhaled therapeutics react with specific lung regions and immune cells and developing new models of the human respiratory system.

What motivates their work on the modeling component, Fromen explained, is that there are currently only limited ways to test new inhaled drugs, ranging from devices that don’t accurately mimic the inner workings of an actual lung to animal models whose physiology doesn’t map very well to that of a human. This makes it especially challenging to predict precisely where new therapeutics will end up once they are inhaled.

“You can make a great formulation, but you can't test it very easily without a good model. And that’s where our group fits: We’re one of the few that does both,” Fromen said. “There’s also very few groups that think about how those treatments become aerosols and how aerosols then are delivered efficiently to the lung, so we’re also unique in that space.”

Lattice structures for mimicking lung function

Fromen received a Faculty Early Career Development Program (CAREER) award from the National Science Foundation (NSF) to study how aerosols move through 3D printed structures that will form the basis of a state-of-the-art model of the human lung. Starting July 1 and with a five-year, $615,000 award, the lab members will use their expertise to study aerosol movement in these unique structures.

Because the lung is so complex, it’s impossible to construct every single airway that’s present, Fromen explained. “Instead, we are thinking about how we can develop a good approximation of what goes on inside the lung that gets us the spatial deposition of a person so we can figure out where inhaled medicines are going,” she said.

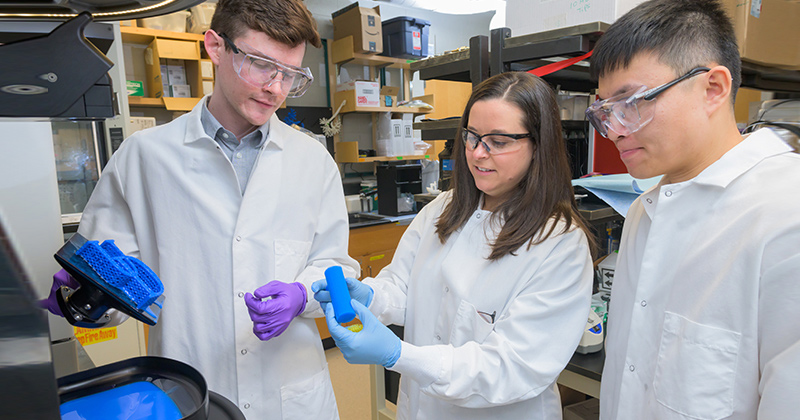

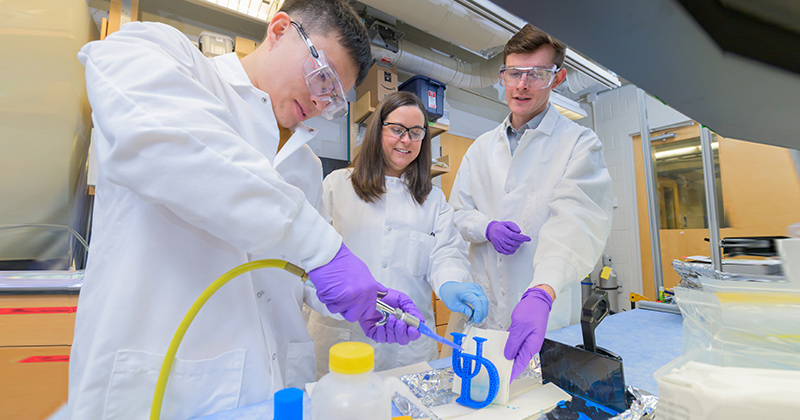

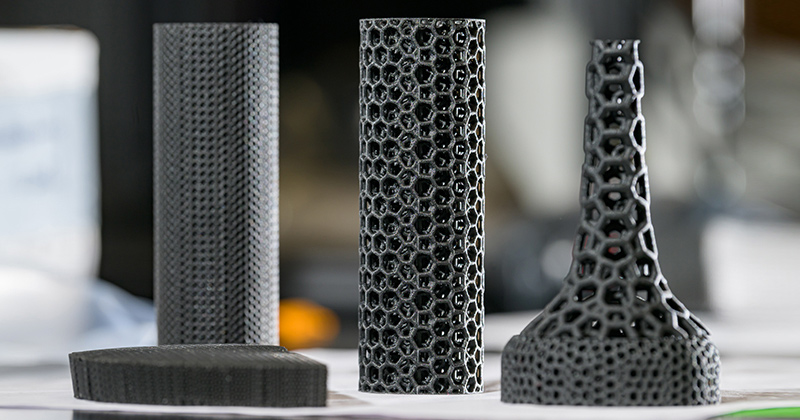

To do this, the group is using additive manufacturing to 3D print open, porous structures called lattices. Fromen said, “You can think of these structures as really mediocre filters” but added together, these filters mimic the aerosol filtration that occurs naturally in the lung.

And because Fromen and her research lab can precisely control the geometry of the lattices, they can design and test different configurations in the lab. “With this project, we’re studying how aerosols go through these lattices, and how different geometries, size scales, and the aerosol properties influence how well they're being filtered out,” Fromen said.

One challenge of this project is that, while there is an existing knowledge base on the structural properties of these lattices, there’s a dearth of information about how particles flow through them. “No one has really studied aerosol transport in these before, so there’s no fundamental theory that exists,” Fromen said. “The focus of this grant is to gain a fundamental understanding and to create our own new theories to understand what’s going on. Then, we can figure out how to push the limits of what the lattices can do.”

Thanks to the efforts of doctoral student Ian Woodward, who Fromen said “absolutely pioneered the use of lattices in our lab,” the team has already published two papers. These studies, published in Additive Manufacturing and the AIChE Journal, describe airflow behavior as particles travel through different types of lattice structures.

Once the researchers find the best design, the goal is to print out lattices using elastic materials and set up a full-scale version of a lung that can “breathe,” with Woodward and fellow doctoral student Yinkui Yu taking the lead on this work.

“I’m excited to see how we can build the fundamental understanding that allows us to rapidly implement these in a lung model,” Fromen said. “Because that’s the end goal, and what has been the biggest hold-up so far is finding the right lattice.”

Connecting with communities and supporting students

“Professor Fromen is an incredible researcher and educator whose quantitative approaches to understand and model a highly complex, biological system – the lung – are critically important from both a research advancement and educational standpoint,” said Millicent Sullivan, chair of the Department of Chemical and Biomolecular Engineering. “On the research side, Professor Fromen’s ability to distill the lung architecture into its defining geometric features is providing new understanding of the physicochemical factors that govern inhaled medicine deposition, which in turn will accelerate the translation of new inhaled therapies. On the education side, Professor Fromen’s models enable students to see and test chemical engineering principles in the context of medicine in an entirely new way.”

This CAREER award will also enable Fromen to expand her ongoing efforts around science communication, STEM engagement and education. Plans include local middle school outreach programs, training graduate students on social awareness and communication, and bolstering the engagement of female students enrolled in science and engineering programs at UD.

“What I’m most excited about, and where I think we’ll have the biggest impact, is within my research group and the local UD community to be able to do things for our students that help make them better community citizens,” Fromen said.

Scientifically, Fromen said that her group’s biggest contribution will be the fundamental research that will allow them to create a better model of the lung, which she added could enable new healthcare innovations as well as change how researchers think about treating pulmonary diseases.

But beyond their research achievements, Fromen added that a major part of this project’s impact is all the researchers who will get to work on it. “I'm excited to see how the students take the skills they learn in my lab and find opportunities to use them in new applications, to build their own professional expertise and to be more innovative and creative,” she said. “So it’s the people, and the impact of the students who get to train on this project, that gets to be my legacy.”

Contact Us

Have a UDaily story idea?

Contact us at ocm@udel.edu

Members of the press

Contact us at 302-831-NEWS or visit the Media Relations website