Insights for future innovations

Photo by Evan Krape | Graphic courtesy of Arthi Jayaraman | Illustration by Joy Smoker July 20, 2023

In the lab of UD’s Arthi Jayaraman, researchers are developing new computational tools to enable faster innovations in materials science and engineering

The natural world is full of unique materials. Take the giant blue morpho butterfly — their iridescent wings are an example of a “structural color,” with the vivid blue hue produced not only by pigments but also by the microscopic structures that line the surface.

Nature’s vivid colors are just one example of how a material’s microscopic structure, the three-dimensional arrangement of its individual atoms, influences its properties. Next-generation manmade materials, such as solar cells, batteries and athletic wear, are also made of combinations of atoms that, when arranged in a precise manner, give rise to unique and desirable properties such as conducting energy or wicking away sweat.

Creating new materials with specific properties requires a detailed understanding of these structures at multiple length scales ranging from atomic to micron. But visualizing this multiscale structure while designing a material is often difficult in the lab, making new innovations in materials science and engineering all the more challenging.

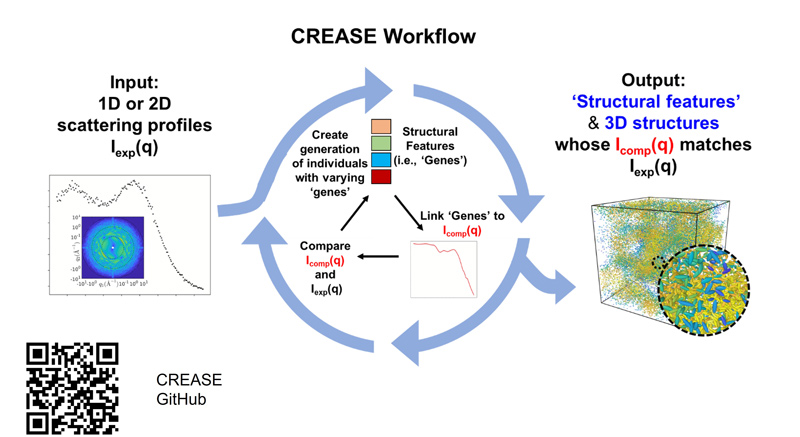

Now, a new computational method developed at the University of Delaware by members of Arthi Jayaraman’s lab enables researchers to interpret this multiscale structural information more easily through the power of machine learning and optimization. Known as Computational Reverse-Engineering Analysis for Scattering Experiments’ (CREASE), this method helps lower the barrier for developing new, innovative materials with important properties and paves the way for future advancements across a variety of fields and applications.

Traditional and modern methods

Jayaraman is the Centennial Term Professor for Excellence in Research and Education in the College of Engineering’s Department of Chemical and Biomolecular Engineering. In Jayaraman’s lab, researchers apply their computational expertise to design new materials and gain a better understanding of their structure and, by extension, their properties. Their work impacts several fields and applications, including energy, optics, photonics, biomedicine and more.

Their efforts are focused primarily on soft materials, which include things like polymers, gels and biomaterials. Jayaraman explained that these types of materials are challenging to study because of their highly diverse length scales and less ordered molecular arrangements as compared to hard materials like crystals. To address this challenge, her group combines traditional computational chemistry approaches, including modeling, simulations and theory, with modern data-driven strategies such as machine learning.

“We collaborate with experimentalists who are looking at these systems in a wet lab,” Jayaraman said of her group’s workflow. “Using our chemistry- or physics-informed or data-driven models, we then validate our computational approaches with experimental predictions. It’s a very nice back and forth.”

Beyond making predictions about new materials and validating the results of experimentalists, several years ago Jayaraman realized that her group could also use their expertise to help researchers better understand how structure relates to a material’s properties. “We realized that we could develop computational methods to analyze what experimentalists are measuring, to clarify what they are observing, which is where the CREASE method came in,” she said.

Power for experimentalists

The advanced imaging techniques, including microscopy, that experimentalists use to see how molecules are arranged in a material only provide a two-dimensional view, Jayaraman explained. To get a 3D perspective, techniques like small-angle scattering are useful, but translating these measurements, which look like point clouds of data, into a “visual” that depicts where each molecule sits is challenging.

Now, CREASE allows experimentalists to determine the 3D, molecular-level spatial arrangement within materials by analyzing small-angle scattering measurements. “CREASE allows experimentalists to convert a very difficult to interpret measurement into something they understand easily,” Jayaraman said. “With CREASE, we provide them with a more direct route to understand what that small-angle scattering measurement means.”

The CREASE method was recently part of a Science Advances paper on structural colors, where Jayaraman’s team and researchers from University of Akron showed how structural colors made by mixtures of strongly absorbing, melanin-mimicking nanoparticles can be predicted with computational reverse-engineering.

Since this Science Advances study was completed, CREASE has been further refined and applied to even more complex materials where it’s not only used to interpret the arrangement of assembled molecules at one condition but how their structure changes under varying conditions, such as an increase in temperature or concentration.

“These three recent papers on CREASE uniquely provide power to experimentalists to get a visualization of the arrangement of molecules, which give rise to desired properties,” Jayaraman said. “Getting insights into that multiscale arrangement is hard, and our CREASE method has enabled that insight.”

High-speed innovation

Now that the latest iteration of their method has been enhanced with machine learning, Jayaraman’s team members are poised to use CREASE to handle even more complex datasets and systems “that might hold even more information like anisotropic structural arrangements'' from small-angle scattering measurements, Jayaraman said. (Anisotropic relates to a material that has different properties based on which direction is being measured. A classic example is wood grain, which can hold more weight along its grain than across).

Another goal of this latest iteration of CREASE is to facilitate the analysis of high-throughput data, where measurements on new materials are coming in faster than researchers can analyze and interpret them. “People want methods that they can put in the middle of a workflow, right after the measurements are collected, to enable faster interpretation as part of an automated design loop that will make materials design, innovation and discovery faster,” she said.

Whether that material is an even brighter blue or a component of a new electric car battery, Jayaraman’s group, and their innovative computational methods, will help bring them to life.

To learn more about CREASE method and how it can be applied to material systems, please visit the method overview website on GitHub: https://crease-ga.readthedocs.io/en/latest/

Contact Us

Have a UDaily story idea?

Contact us at ocm@udel.edu

Members of the press

Contact us at 302-831-NEWS or visit the Media Relations website