UD Professor Norm Wagner: youtube.com/watch?v=e0q19PlC8ic

Prof. Norm Wagner to present Francis Alison Lecture

Photos by Kevin Quinlan, NASA and courtesy of Norm Wagner | Video by Ally Quinn October 22, 2021

Wagner will speak Nov. 3 on nano and molecular engineering in service of exploration, education and entrepreneurship

Editor’s note: Prof. Norman Wagner, the 2020 recipient of UD’s Francis Alison Faculty Award, will present the Francis Alison Lecture on “Nano and Molecular Engineering in Service of Exploration, Education and Entrepreneurship” at 4 p.m., Wednesday, Nov. 3, in the Gore Recital Hall of the Roselle Center for the Arts. Register for the in-person event here. A livestream also will be available. The UDaily story below was first published in the fall of 2020 when Wagner was awarded the honor.

Ever since he found a trigonometry textbook hidden in the walls of the old farmhouse his parents were renovating, Norm Wagner has been trying to crack one code or another.

He was in sixth or seventh grade when that book and several others emerged from the walls of his family’s pre-Civil War house in Cambridge Springs, Pennsylvania.

“It was Greek to me with the math and the symbols,” he said. “But things like that spark your curiosity. Finding a book in the wall had to be something special. I had to crack the code.”

Wagner’s lifelong curiosity and delight in science, research and collaborative problem-solving have fueled an inventive career that has inspired many a colleague and student, drawn international recognition and now is distinguished with the University of Delaware’s highest faculty honor — the 2020 Francis Alison Award. The award, established in 1978, is named for the University’s founder, the Rev. Francis Alison, and recognizes contributions and distinction as both a scholar and an educator.

Wagner, who joined UD’s faculty in 1991, is the Unidel Robert L. Pigford Professor of Chemical and Biomolecular Engineering, a chair named for the University’s first Alison Award winner.

One of the many students Wagner has mentored — Matthew Helgeson, now an assistant professor of chemical engineering at the University of California-Santa Barbara — said Wagner’s delight in discovery was a memorable and powerful influence on him and many others.

“I have often described Norm’s advising style as one in which he works himself into a euphoric frenzy over research progress, which then (hopefully) rubs off on the student,” Helgeson wrote in a letter of endorsement. “No result is too minor, no idea too small to escape his sense of excitement for his students’ work.

“Norm is in the students’ labs and offices on a daily basis, talking to students about their latest results and driving them forward to next steps. One of the most common refrains during these conversations — ‘How can you sleep without doing this?’ — is emblazoned into the minds of all former Wagner group members. It is not meant as admonishment, but rather incredulousness at any level of enthusiasm that does not match his own.”

Wagner traces his fascination with science to 1969, the day he saw astronauts Neil Armstrong and Buzz Aldrin walk on the surface of the moon. Now his work may help NASA accomplish its Mission to Mars.

His inventive ideas in engineering, materials science and physics have won international acclaim and placed him at the highest levels of influence in multiple scientific communities. But the Francis Alison Award is especially gratifying, he said, coming as it does from his closest colleagues and the community he said he can’t do without.

“This is really special,” he said in a recent interview with UDaily. “To me, it’s the highest honor I can receive…. But this award is not about me — it’s about the community that has supported me through the years. A lot of people in the unique environment of Delaware enabled me to achieve this. It’s the broader enterprise of faculty and students and academic administrators who helped support me, especially the staff and everybody who makes the wheels of the bus go ‘round.”

He has returned the favor, with pioneering work that has marked the University as a leader in rheology (the study of how complex materials flow) and the use of neutron scattering techniques, which allow study of complex fluids at the molecular level.

“Norm is one of the leading international figures in colloid science and the rheology of particulate systems, areas central to chemical engineering,” wrote John F. Brady, Chevron Professor of Chemical Engineering at the California Institute of Technology. “Rarely has one individual contributed on all three fronts of experiment, theory and computation and pushed forward the basic understanding of complex microstructured materials. But Norm has gone well beyond a ‘basic understanding.’ He has used his knowledge of colloidal behavior to actually tailor new materials for practical application.”

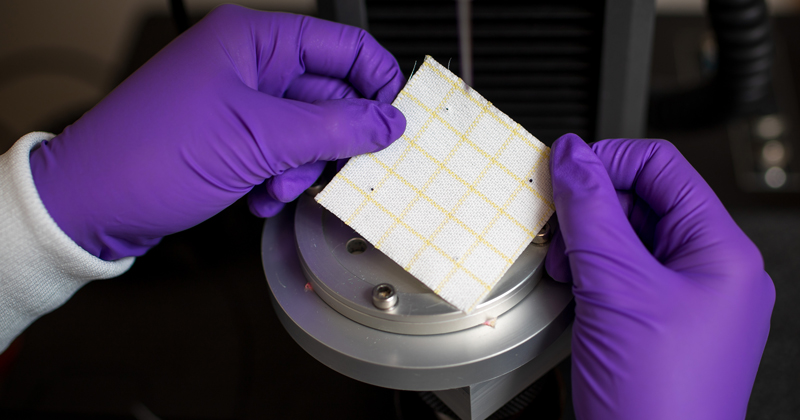

Brady pointed to Shear Thickening Fluid (STF), certainly the most famous of the inventions and 18 patents that have emerged from Wagner’s laboratory. When integrated into fabrics, it provides responsive and fascinating new properties, making the fabric stronger or stiffer when under stress, then returning to normal when that stress is gone. It adds puncture resistance to Kevlar, for example, to protect those in harm’s way, it solves process problems for industry, holds promise for NASA’s future trips to the moon and its Mission to Mars and now provides new support in Reebok garments for female athletes, to name just a few applications.

STF and serendipity

Wagner said the discovery of STF is a prime example of how collaborative communities produce unexpected connections and discoveries.

Shear thickening is a phenomenon that describes how the viscosity of some fluids or soft matter increases when under stress. It can be a big problem in industrial processing, preventing proper pumping and flowing, for example.

A student — John Bender — wanted to pursue that problem and Wagner discouraged the idea at first. It’s a big problem. But Bender persuaded him, Wagner said, and they started working on it.

It was a decade later that Wagner got an unexpected question about whether the shear thickening phenomena might be harnessed in helpful ways.

He went to a talk at UD’s Center for Composite Materials, where a surgeon from Walter Reed Army Hospital was speaking on the need for additional protective equipment for troops — specifically, ways to protect their extremities. Regular body armor couldn’t be wrapped around an arm or leg and the Department of Defense was looking for solutions.

During lunch that day, a researcher from the Army Research Laboratory was at Wagner’s table. She had heard about his work with shear thickening. Could that be part of the solution for new protective materials?

That connection ultimately led to STF — also known as “Liquid Armor” — invented in collaboration with Eric Wetzel, a UD mechanical engineering alum who by then was a scientist at the U.S. Army Research Lab.

“That was serendipity,” Wagner said. “I hadn’t thought of using it in a positive way until we were motivated to develop flexible body armor to protect soldiers.… That is one of the advantages of being at a university. You get exposed to lots of different ideas and challenges.”

That exchange of perspectives and expertise, guided by the scientific method, makes all kinds of discovery possible.

“True science is where you embark not knowing where the answer is,” he said. “Sometimes you are surprised by the observations you see, the experiments you do or the theory you derive. It predicts something that isn’t what you expected or you see something that wasn’t expected. And that is the exciting part of science.

“For graduate students, it’s their nightmare. They say, ‘Oh, no, it’s not working how we thought it should.’ And of course you’ve got to go back into the lab and do it again. You want to make sure your work is correct, but at some point you have to accept that there is something exciting and new here. That can twist and turn and take your thesis in very different directions.”

Great mentors help students navigate those transitions.

“You trust in the scientific method,” he said. “If you do it right, you will get an answer. It may not be the answer you wanted. It may be a different answer, but that answer will be the correct answer, giving you some guidance and allowing you to move forward.”

For Wagner, that’s how innovation and invention happen.

“The idea that there’s a ‘Eureka!’ moment — those are almost always wrong,” he said. “You have a ‘Eureka!’ idea in the shower, while you’re thinking, contemplating, sitting on the back porch, thinking about your work, working something out. The ‘Eureka!’ thought is almost invariably wrong. But it was important to have because it creates excitement — let me explore this. Then you apply the scientific method and the elbow grease that goes with it and you end up somewhere interesting.”

Leadership and impact

Wagner’s ideas have put him in the top echelons of scientific leadership. He was elected to the National Academy of Engineers (2015), the National Academy of Inventors (2015), is a fellow of the American Association for the Advancement of Science (2014) and the Neutron Scattering Society of America (2014). He won the Bingham Medal of the Society of Rheology (2014) and the Paul Siple Memorial Award of the Army Research Conference (2002).

His research has drawn millions in support, which has — in turn — supported the research of many others.

He is the co-founder of the Center for Neutron Science, which has a cooperative research agreement with the U.S. Department of Commerce’s National Center for Neutron Research, and now leads an $11 million project for the National Science Foundation that will provide a neutron spin echo instrument at the National Institute of Standards and Technology (NIST) which will be accessible to all researchers.

His startup company STF Technologies — co-founded with UD alum Richard Dombrowski in 2003 — is working with NASA to develop STF-infused materials that will better protect astronauts in future missions to the moon and Mars. The International Space Station now has its third STF Technologies experiment aboard and Wagner’s team hopes to have an experiment on the lunar surface soon.

“You’re challenged by these questions that no one has asked of these materials before,” Wagner said. “No one has put them in these environments. We don’t know how they’re going to respond…. Every few months we learn a little bit more about the Martian environment, the lunar environment, the space environment more generally — that’s horrifyingly more difficult problems to solve. And that requires a lot of retrenching, digging back, thinking, working forward, working the problem, looking for solutions. We wouldn’t do that if we just stayed on Earth. None of those questions would come up.

“And the fun thing about it is — as we answer those questions that deal with what we want to do in these extreme environments, we start to develop materials that have clearly superior properties back here on Earth.”

Three academic generations now can trace their work to Wagner, who has mentored 52 doctoral students, 32 postdoctoral researchers, nine master’s students and 37 undergraduate researchers.

Lynn Walker, professor of chemical engineering at Carnegie Mellon University, is one of them.

“Being a first Ph.D. student of a faculty member is a special privilege,” she wrote. “Norm’s enthusiasm, excitement and curiosity were unbounded and infectious. Norm has incredible physical insight and technical skill and passes these on to students with patience…. He reached out to senior faculty in the department and other departments to help with our growth as independent researchers; from connecting us to editors to learn about the peer review process to encouraging me to be a teaching fellow. Norm also taught us that collaboration is a powerful tool in modern research and encouraged us to attend conferences, ask questions and feel free to talk to other researchers about our work and potential collaborations.”

Wagner has taught in classrooms and conferences around the world and has been a visiting professor in Germany, Switzerland, Italy and Sweden. He has published more than 200 scientific articles and served on the editorial boards and executive committees of multiple journals and scientific societies.

His work has had continuing benefit for industry, too, not only in improving processes and approaches but also in developing leaders in the field.

Rebekah Cooper, now head of the Heavy Oils Process Department at ExxonMobil’s Beaumont (Texas) Refinery, worked in Wagner’s lab at UD as part of the Undergraduate Research Program.

“This was my first time working in a professional, engineering environment with a diverse and driven group of students who were working towards a singular goal,” Cooper wrote. “Norm was an exceptional mentor, with a passion for his research work and a seemingly unlimited amount of patience to guide and instruct all these undergrads who had just walked into a functioning research lab for the first time. Norm taught me through my research project to think abstractly, problem solve, work as a team, and most importantly, follow my instincts. These became the foundational building blocks of my professional career.”

Michelle Calabrese, assistant professor of chemical engineering and material science at the University of Minnesota, said Wagner helped students gain confidence in their own ideas — not an easy bridge to cross for many.

“As a woman in engineering, it is easy to discount your ideas or your ability to be successful in academia when you see so few female faculty members,” she wrote. “However, Norm was always encouraging me to pursue what I wanted to work on, and he rarely said no to an idea. I was always allowed to write proposals on whatever aspects of the research I wanted, which gave me ownership of (and made me more invested in) my ideas. While I had no background in rheology when I joined Norm’s group, I never felt my background was a detriment. In many groups, my knowledge gap could have been demoralizing, but Norm never made me feel behind despite starting in an entirely new field. I’ve taken this lesson to heart and have now taken the same approach in recruiting my own graduate students.”

Proving grounds

The son of a chemistry professor and a high school English teacher, Wagner said he took advantage of the opportunity to sit in on lectures at the small college where his father taught. One of those classes was an astronomy class, which fed his fascination with the moonwalk of Neil Armstrong and Buzz Aldrin.

“You look up in the sky and see the moon and you think, ‘Gee, these guys are up there,’” he said. “You like to be part of things like that. Science was very important to me growing up. In a sense it was very inspirational. I was always outside in nature, interested in lots of things I saw with my own eyes and encouraged by a family that was oriented that way.

“When I got into college, I got interested in chemistry,” he said. “But I wanted to know — how do you use chemistry to help people? And that’s how I got into chemical engineering.”

Wagner earned his bachelor’s degree at Carnegie Mellon University in Pittsburgh and his doctorate at Princeton University, where his advisor was Prof. William B. Russel, a preeminent colloid scientist. He was a NATO postdoctoral fellow at the University of Konstanz (Germany) and did further postdoctoral research at the Department of Energy’s Los Alamos National laboratory before joining the UD faculty in 1991.

He can point to the influence mentors and collaborators and researchers from around the world had on him at every point of decision in his career.

He named the late Arthur Metzner as one of the reasons he came to UD — and stayed. Metzner was a major reason UD emerged as a leader in rheology and neutron-scattering techniques.

“He was a great rheologist,” Wagner said, “and he taught me many great things through his own loyalty to Delaware. He showed how you can be a department chair and then go back on the faculty. Jon Olson, who started the Faculty Senate, encouraged me to look out across the University and build friendships and collaborations. That was great advice. I have met phenomenal people in all disciplines at this University, that make it a wonderful place to work. When I became department chair, those connections and ties were extremely valuable.”

A fourth dimension

One of the best things about discovery is the way it points to something else you really should explore.

Wagner is doing that, of course.

He and others who study soft matter and complex materials are moving from their 20th century focus on three-dimensional structure and function and the promise of nanomaterials to a fourth dimension: Time.

“Processing matters, how materials are used matters, but it’s not just that I create a structure and then I’m done,” he said. “Now a lot of things we’re looking at involve time. Drug delivery, for example. We’re structuring nanoparticles that transform and do things in your body. They’re not static structures. They’re constantly asked to do things that change with time.”

Analyzing such phenomena requires specialized instruments and Wagner now is leading a National Science Foundation-funded project to build a new Neutron Spin Echo Spectrometer at the National Institute for Standards and Technology’s Center for Neutron Research. Bringing that world-class instrument to the United States will allow researchers to study the behavior of proteins and nanoparticles over time.

“These experiments will unlock phenomena that will raise new questions that will allow us to analyze and design new materials,” he said. “We need the tools — the microscopes — that not only look at the structure but time-dependent behavior at the nanoscale.”

What scientists learn about proteins and monoclonal antibodies and drug delivery using these tools could have a game-changing impact on our world and its wellbeing.

“Developing vaccines and therapeutics for diseases such as the novel coronavirus COVID-19 may depend on that ability,” he said.

And the questions that arise in the process will point to other great discoveries.

“Just asking good questions is more important than being inspired,” Wagner said. “Science will get you to the answer, but you have to have the question first.”

Contact Us

Have a UDaily story idea?

Contact us at ocm@udel.edu

Members of the press

Contact us at 302-831-NEWS or visit the Media Relations website