NIIMBL-led team selected for $10.5 million Gates Grand Challenges funding award

Photo by Daniel Maiese October 23, 2025

Project aims to produce lifesaving therapies at lower cost

When you catch a cold, your immune system jumps into action. Antibodies — your body’s natural defenders — block and neutralize the virus, marking the invader for destruction by other immune cells.

Monoclonal antibodies (mAbs) are lab-made proteins that work in a similar way. They’re designed to target harmful cells with precision, making them powerful tools in treating illnesses such as the flu, cancer, autoimmune diseases like lupus and rheumatoid arthritis, neurological conditions such as multiple sclerosis and even allergic reactions. But creating these therapies is complex and costly.

A research team led by the University of Delaware’s Kelvin Lee is working to change that. Lee, the Gore Professor of Chemical and Biomolecular Engineering at UD, has received $10.5 million in funding through the Gates Grand Challenges Program aimed at significantly lowering the cost of manufacturing these vital treatments.

The project will be carried out by a collaboration of industry and academic partners, including many from the National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMBL). Lee serves as director of NIIMBL, a public-private partnership of more than 200 member organizations — including industry, academia and government — working to accelerate biopharmaceutical innovation and develop a skilled workforce for the industry. Headquartered on UD’s Science, Technology and Advanced Research (STAR) Campus, NIIMBL is part of Manufacturing USA, a diverse network of 18 federally sponsored manufacturing innovation institutes.

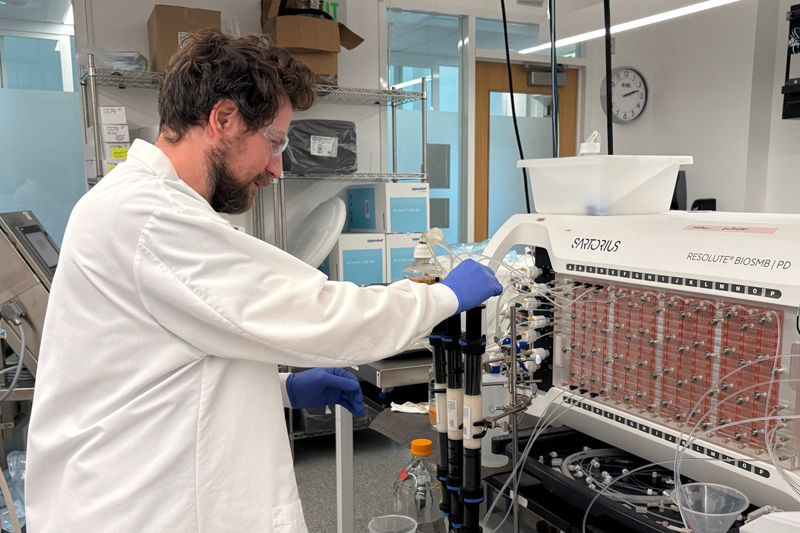

Over the next three years, key partners on the project, including UD, Sartorius, Rensselaer Polytechnic Institute and Enquyst Technologies, will demonstrate technologies that are expected to substantially reduce the cost to manufacture therapeutic antibodies, enabling broader access to these types of medicines. Additional contributors include Penn State, Michigan Technological University and University College London.

“We are excited by the opportunity to demonstrate that there are existing solutions developed by industry and academic partners that can significantly reduce cost of goods and accelerate timelines,” Lee said. “We are honored to receive this grant from the Gates Foundation, which will enable this exceptional team to deliver meaningful advances to antibody production efficiency.”

MAbs offer targeted treatments for a range of conditions such as infectious diseases, cancer and autoimmune disorders that affect millions globally. However, while these therapies are widely available in the developed world, they are too expensive to produce to support the needs of low- and middle-income countries due to the complexity of the manufacturing process, stringent regulatory requirements, costly raw materials and significant infrastructure investments.

This Grand Challenge is focused on making an anti-malarial antibody at low cost. The learnings and technology will, however, be applicable to manufacturing all mAbs, Lee said. Globally, 263 million malaria infections and 597,000 deaths from the disease occurred across 83 countries in 2023, according to the World Health Organization.

The project team brings together specialized expertise in technologies, economic modeling and manufacturing processes. The team will coordinate efforts over the lifespan of the award to test and demonstrate new approaches to mAbs manufacturing that can be used as a basis to achieve the “$10 per gram” goal set out by the Gates Grand Challenge.

“We are enthusiastic about this opportunity to coordinate the innovations that Sartorius brings with promising, novel workflows,” said Benham Partopour, Principal Scientist at Sartorius Corporate Research. “This funding will help bring life-saving therapies to patients.”

“Optimization and intensification of the downstream purification process offer the exciting possibility of breaking through to the $10/g overall target," said Todd Przybycien, professor and department head of Rensselaer Polytechnic Institute’s Department of Chemical and Biological Engineering. "We are excited to advance the precipitation-based process we have developed with our collaborator at Penn State as part of the manufacturing solution to sustainably meet the global need for monoclonal antibodies.”

"Enquyst has been eager to scale up our disruptive downstream processing technology and to deliver substantial cost reductions to the global biologics market," said Enquyst's founder and Chief Scientific Officer, Jason Criscione. "The framework that we've proposed in this project is an exciting step toward achieving this goal, and we are grateful for the support from the foundation."

This particular Grand Challenge is in honor of Dr. Steve Hadley, former senior program officer at the Gates Foundation, who championed the reduction of mAbs manufacturing costs to make life-saving treatments affordable and accessible.

Work on this project will happen at partner locations, as well as at NIIMBL’s next-generation manufacturing platform in the Ammon Pinizzotto Biopharmaceutical Innovation Center on STAR Campus.

About NIIMBL

The National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMBL) is a public-private partnership whose mission is to accelerate biopharmaceutical innovation, support the development of standards that enable more efficient and rapid manufacturing capabilities, and educate and train a world-leading biopharmaceutical manufacturing workforce, fundamentally advancing U.S. competitiveness in this industry. NIIMBL is part of Manufacturing USA®, a diverse network of federally sponsored manufacturing innovation institutes, and is funded through a cooperative agreement with the National Institute of Standards and Technology (NIST) in the U.S. Department of Commerce with significant additional support from its members. For information, visit www.niimbl.org.

Contact Us

Have a UDaily story idea?

Contact us at ocm@udel.edu

Members of the press

Contact us at mediarelations@udel.edu or visit the Media Relations website