ADVERTISEMENT

- Rozovsky wins prestigious NSF Early Career Award

- UD students meet alumni, experience 'closing bell' at NYSE

- Newark Police seek assistance in identifying suspects in robbery

- Rivlin says bipartisan budget action, stronger budget rules key to reversing debt

- Stink bugs shouldn't pose problem until late summer

- Gao to honor Placido Domingo in Washington performance

- Adopt-A-Highway project keeps Lewes road clean

- WVUD's Radiothon fundraiser runs April 1-10

- W.D. Snodgrass Symposium to honor Pulitzer winner

- New guide helps cancer patients manage symptoms

- UD in the News, March 25, 2011

- For the Record, March 25, 2011

- Public opinion expert discusses world views of U.S. in Global Agenda series

- Congressional delegation, dean laud Center for Community Research and Service program

- Center for Political Communication sets symposium on politics, entertainment

- Students work to raise funds, awareness of domestic violence

- Equestrian team wins regional championship in Western riding

- Markell, Harker stress importance of agriculture to Delaware's economy

- Carol A. Ammon MBA Case Competition winners announced

- Prof presents blood-clotting studies at Gordon Research Conference

- Sexual Assault Awareness Month events, programs announced

- Stay connected with Sea Grant, CEOE e-newsletter

- A message to UD regarding the tragedy in Japan

- More News >>

- March 31-May 14: REP stages Neil Simon's 'The Good Doctor'

- April 2: Newark plans annual 'wine and dine'

- April 5: Expert perspective on U.S. health care

- April 5: Comedian Ace Guillen to visit Scrounge

- April 6, May 4: School of Nursing sponsors research lecture series

- April 6-May 4: Confucius Institute presents Chinese Film Series on Wednesdays

- April 6: IPCC's Pachauri to discuss sustainable development in DENIN Dialogue Series

- April 7: 'WVUDstock' radiothon concert announced

- April 8: English Language Institute presents 'Arts in Translation'

- April 9: Green and Healthy Living Expo planned at The Bob

- April 9: Center for Political Communication to host Onion editor

- April 10: Alumni Easter Egg-stravaganza planned

- April 11: CDS session to focus on visual assistive technologies

- April 12: T.J. Stiles to speak at UDLA annual dinner

- April 15, 16: Annual UD push lawnmower tune-up scheduled

- April 15, 16: Master Players series presents iMusic 4, China Magpie

- April 15, 16: Delaware Symphony, UD chorus to perform Mahler work

- April 18: Former NFL Coach Bill Cowher featured in UD Speaks

- April 21-24: Sesame Street Live brings Elmo and friends to The Bob

- April 30: Save the date for Ag Day 2011 at UD

- April 30: Symposium to consider 'Frontiers at the Chemistry-Biology Interface'

- April 30-May 1: Relay for Life set at Delaware Field House

- May 4: Delaware Membrane Protein Symposium announced

- May 5: Northwestern University's Leon Keer to deliver Kerr lecture

- May 7: Women's volleyball team to host second annual Spring Fling

- Through May 3: SPPA announces speakers for 10th annual lecture series

- Through May 4: Global Agenda sees U.S. through others' eyes; World Bank president to speak

- Through May 4: 'Research on Race, Ethnicity, Culture' topic of series

- Through May 9: Black American Studies announces lecture series

- Through May 11: 'Challenges in Jewish Culture' lecture series announced

- Through May 11: Area Studies research featured in speaker series

- Through June 5: 'Andy Warhol: Behind the Camera' on view in Old College Gallery

- Through July 15: 'Bodyscapes' on view at Mechanical Hall Gallery

- More What's Happening >>

- UD calendar >>

- Middle States evaluation team on campus April 5

- Phipps named HR Liaison of the Quarter

- Senior wins iPad for participating in assessment study

- April 19: Procurement Services schedules information sessions

- UD Bookstore announces spring break hours

- HealthyU Wellness Program encourages employees to 'Step into Spring'

- April 8-29: Faculty roundtable series considers student engagement

- GRE is changing; learn more at April 15 info session

- April 30: UD Evening with Blue Rocks set for employees

- Morris Library to be open 24/7 during final exams

- More Campus FYI >>

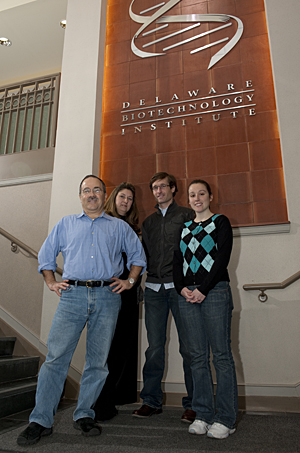

9:45 a.m., Jan. 15, 2010----Born from research conducted in an academic laboratory, Elcriton Inc. was created in December 2008 to develop innovative technologies to address sustainable energy and chemical production in the United States and beyond. The company evolved from work in the laboratory of Eleftherios (Terry) Papoutsakis, Eugene du Pont Chair of Chemical Engineering at the University of Delaware, and president of Elcriton.

Elcriton is housed in the Delaware Biotechnology Institute (DBI) and conducts research supported by Small Business Innovation Research Grants (SBIR) from both the National Science Foundation (NSF) and the US Department of Energy (DOE).

“National policy is moving us towards alternative fuels. The bioengineering work in our lab, and the opportunity to pursue this important direction through a new enterprise, is very exciting,” said Papoutsakis.

The Energy Independence and Security Act of 2007 (EISA) mandated that 16 million gallons a year of transportation fuel be replaced with biofuel, which is fuel made from renewable, sustainable agricultural waste also known as biomass. Currently, the gasoline supplement consumers see at the pump is ethanol, which is often made from direct food sources, like corn.

The goal of EISA is to promote research and commercialization of next-generation biofuels that are better replacements of gasoline compared to ethanol, and are produced from waste biomass, such as corn stalks. EISA success will ultimately protect the country's food supply, create a sustainable means for domestic fuel production and benefit the environment by reducing greenhouse gas emissions.

Elcriton is immediately addressing EISA goals by developing a bacterium that will convert biomass into a biofuel called butanol.

“We are actively working on designing what we believe to be better bacteria to help in this process to convert biomass into biofuel,” said Bryan P. Tracy, lead scientist and principal investigator for Elcriton.

Tracy also noted some of the challenges associated with ethanol, the prevalent biofuel available to consumers at the pump. Ethanol is corrosive and absorbs water, making it hard to transport in gasoline pipelines. In addition, ethanol requires engine modifications when used at high blends with gasoline.

Today, consumers see “E10” or the like at gas pumps indicating that the fuel is a mix of 10 percent ethanol and 90 percent gasoline. However, ethanol cannot be used in its pure form or at high blends (for example “E85”) in a vehicle without flex-fuel modifications.

In contrast, butanol is less corrosive, and does not absorb water as well. Thus, it can be pumped through the current gasoline infrastructure, and be used in essentially all car engine technologies, even as pure butanol.

Through the genetic engineering of bacteria, Elcriton hopes to achieve a one-step process of adding the bacterium to the biomass and watching it convert the biomass into fuel. Elcriton is currently working to expand and create partnerships with companies that can assist in mass-producing butanol in the near future.

Their goal for commercial production is before the end of 2013. However, biofuel is just the first venture for this fledgling company.

“Elcriton is focused on biofuels now, but we are allowing our innovations to lead the way into new opportunities to replace fossil fuel chemical production with renewable, biomass derived chemicals,” said Papoutsakis.

Elcriton is just one of several companies that have been formed through work in the labs at DBI, and is focused on sustainable, environmentally friendly energy resources for the future of this country and others.

Article by Laura Crozier

Photo by Kathy F. Atkinson