University of Delaware researchers aren't tilting at windmills when it comes to solving energy challenges. Earlier this year, they proved that electric cars, equipped with technology invented at UD, can send battery power back to the grid, earning cash for the owner while helping to balance grid flow. ISE Lab is destined to foster plenty more innovation.

SPARKING ENERGY SOLUTIONS

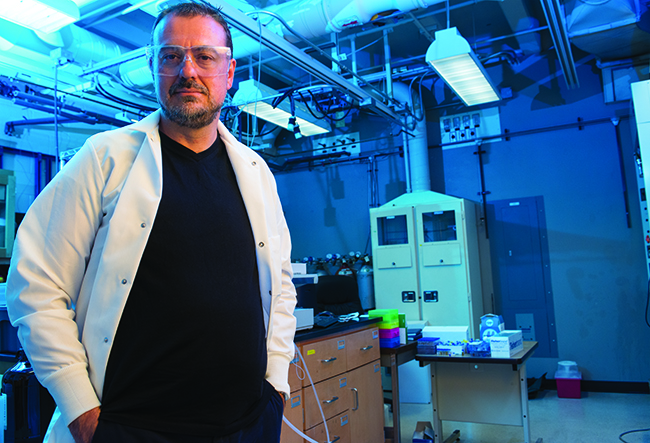

Dion Vlachos leads the Catalysis Center for Energy Innovation. His team aims to find new catalysts—compounds that spark faster, more efficient chemical reactions—for transforming plant matter, or biomass, into biofuel, useful chemicals and electricity.

Biomass, wind, solar, fuel cells—all have a part to play in future energy solutions, according to Michael Klein, director of the University of Delaware Energy Institute (UDEI).

UDEI's role is to bridge the various academic disciplines that support these energy areas and get people working together.

Klein sees ISE Lab, UDEI's new home, as a powerful connecting force for bringing together the 250 people across campus engaged in energy research.

"There is no single science base to energy," Klein says, "but to develop energy solutions we need coherent, functional teams that can compete for multi-year, high-dollar grants that really will make a difference."

Case in point: in 2009, the U.S. Depart- ment of Energy awarded UD a five-year, $17.5 million grant to establish the Catalysis Center for Energy Innovation (CCEI) as an Energy Frontier Research Center—one of 46 research accelerators nationwide working to establish the scientific foundation for a fundamentally new U.S. energy economy.

The CCEI attracts significant federal and industry investment in simple catalytic technologies to transform plant biomass into fuels, chemicals and electricity.

Dion Vlachos, the center's director and Elizabeth Inez Kelley Professor of Chemical and Biomolecular Engineering, is coordinating 12 teams—at UD and 11 other institutions and national laboratories—aimed at making scientific contributions that will lead to energy independence for the United States.

It is challenging work.

"Using a synergistic team approach, we leverage complementary expertise of CCEI faculty across the nation to solve complex problems and realize significant advances much faster than those working alone," Vlachos says.

With a central focus on biomass conversion, the center's major breakthroughs include discovering potential ways to produce plastics from plants, promoting the use of direct carbon fuel cells for converting biomass to electricity, and replacing biological processes with thermochemical processes to transform trees into corn syrup that can be used in food or be transformed into fuels and chemicals.

In parallel, CCEI has a concerted effort toward spin-off technologies and the development of computational and experimental tools that can be applied in other disciplines. The center provides a pathway to transfer these technologies and tools to industry, while training students and postdoctoral researchers—the next generation of engineers—for cutting-edge research.

Vlachos says ISE Lab's first-rate facilities will enable CCEI to develop new materials, test materials created by researchers at collaborating institutions and attract new industrial partners. It will also provide a showcase for renewable fuels and chemicals developed by the center, as well as an integrated demonstration system that can be used as an educational tool to illustrate the center's work to industry, granting agencies, other collaborators and students.

"I see ISE Lab as an incubator that will enhance our research, nurture new synergies on campus and foster opportunities to in- crease collaborations with industry here and across the nation," he says.—Karen Roberts

As a boat propeller spins, the motion leaves a churning wake of water behind. A similar effect occurs with wind turbines, but instead with forceful swirls of air.

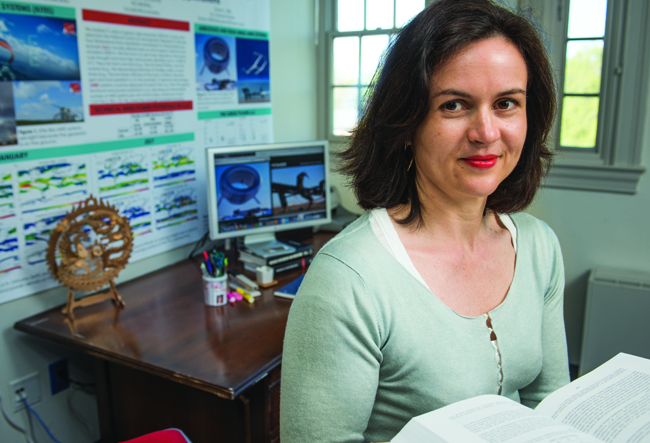

Cristina Archer in UD's College of Earth, Ocean, and Environment is studying airflow patterns in relation to offshore wind farms. "The research I'm conducting right now is using very sophisticated computer models to study what happens downwind of turbines," says Archer, who is an associate professor of geography and physical ocean science and engineering.

The arrangement of wind turbines within a farm could potentially save millions of dollars when the turbines are set up to minimize interactions with each other. Turbines generate electricity by extracting kinetic energy from wind, and wakes disrupt that flow. Reducing the losses that wakes cause from 15 percent down to 10 percent may seem small, but when multiplied by hundreds of turbines can easily add up to substantial savings.

Archer and her Atmosphere and Energy Research group are crunching numbers to figure out optimal ways to place turbines offshore. As a starting point they are simulating an existing offshore wind farm in Sweden that has 48 turbines, modeling the turbine wakes and seeing what happens with shifts in the configuration.

The calculations require millions of data points on wind speed, atmospheric pressure, temperature and other atmospheric variables, requiring huge amounts of computer power and weeks—or even months—to run.

"It's really computer intense," Archer says.

Archer is moving to ISE Lab with others associated with the Center for Carbon-free Power Integration because of the interdisciplinary nature of the work and opportunities for her students to interact with those in other fields, especially engineering students doing the similarly rigorous math needed to conduct simulations.

Archer also studies how much wind there is on a global scale and is exploring the potential for kite-like airborne wind turbines, which are suspended hundreds of feet off the ground by tethers. She summarized issues related to the technology at a conference in Berlin this summer. While her work is applicable to renewable energy applications, it is grounded in her expertise in meteorology.

"Basically I'm a meteorologist and an engineer, and so wind power is a natural merge of the two," Archer says. "I look at technologies of energy from a meteorological point-of-view."—Teresa Messmore

ADVANCED MAGNET DEVELOPMENT: AN INTERNATIONAL QUEST

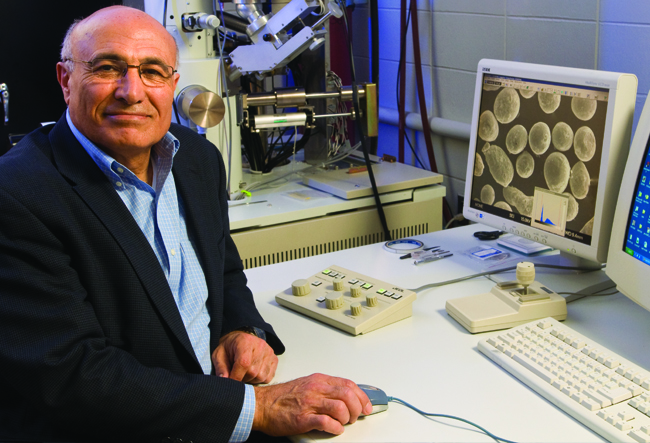

George Hadjipanayis, the Richard B. Murray Professor of Physics and Astronomy at UD, is world renown for his knowledge of magnets. In 2012, he was named a distinguished lecturer by the Magnetics Society of IEEE, the largest professional association for the advancement of technology. One of only three scholars selected internationally for the honor, Hadjipanayis traveled to universities in 13 countries during the year, sharing his expertise and forging new collaborations.

Your car uses at least 30 of them.

Anything with a generator that turns, from a refrigerator to a wind turbine to an airplane to a high-tech security system, has them: magnets.

The problem is that most permanent magnets are made from the same recipe of metals, and some of the ingredients are getting scarce. China has the largest deposits of neodymium, a key metal for magnet-making, but the supply is dwindling.

George Hadjipanayis, the Richard B. Murray Professor of Physics and Astronomy at UD, pioneered the development of the permanent magnets that dominate industry today, used in electric motors to computer hard drives. Thirty years ago, he published the first research on these magnets, which are made of soft, silvery neodymium, its metallic "green twin" called praseodymium (which slowly turns green when exposed to air), iron and boron.

Now, he's leading a team racing to develop the next generation of magnets. The goals: make them less reliant on rare metals and twice as strong.

"Stronger magnets allow for lighter, smaller, more energy-efficient devices," he explains.

Hadjipanayis won a $4.4 million grant from the U.S. Department of Energy's Advanced Research Projects Agency (ARPA-E) in 2009 to lead one of six teams nationwide exploring a variety of angles and methodologies for advanced magnet development. The research involves multiple collaborators: chemists, engineers, physicists and materials scientists.

They work with nanoscale quantities of metals such as iron, platinum, samarian and cobalt—particles that are smaller than one-ten thousandth the thickness of a human hair.

They meticulously assemble new composite magnets from the bottom up, viewing details as fine as a single column of atoms with a transmission electron microscope (TEM). They also test the magnets' strength and coercivity, a measure of how resistant the assembled nanocomposites are to becoming demagnetized.

This summer, Hadjipanayis won two contracts from the U.S. Department of Energy to continue the research. ISE Lab will be a major asset to both studies. One project is with Argonne National Laboratory and GE; the other is with Pacific Northwest National Laboratory (PNNL).

"Thirty years ago, the U.S. led the world in magnet technology," Hadjipanayis says. "We're working to help bring that back."—Tracey Bryant