Acid Rain Can Be Prevented Without Compromising Industral Ouput

Acid Rain Can Be Prevented Without Compromising Industral Ouput

Acid Rain Can Be Prevented Without Compromising Industral Ouput

Acid Rain Can Be Prevented Without Compromising Industral Ouput

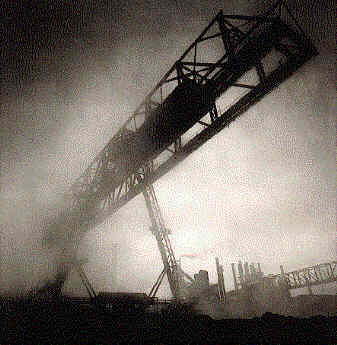

Although the combustion of fossil fuels is necessary to provide the power

that drives our society and industries, it also presents the issue of acid

rain. Acid rain is one of the severest consequences that our society faces

due to engaging in heavy industry. Industrial processes relying on fossil

fuels for power have led to an increase in acid rain due to greater

emissions of gases such as sulfur dioxides (SOx) and nitrogen oxides

(NOx). In the atmosphere these gases react with water to form

acids which cause a downward shift in the pH of the atmospheric water.

This water eventually condenses and falls to the ground as acid rain,

where it has profound effects on the environment and its inhabitants.

The technology exists for the prevention of acid rain with respect to industrial

emissions, yet there is a strong debate over whether the implementation of

such technology is beneficial to the industrial entities. Evidence

indicates that employing various techniques to eliminate acid rain can

ultimately benefit industry and society.

A common

misconception about SO2 emissions is that cars and transportion are

the primary sources. It is important to note that over 93% of all sulfur

dioxide emissions are industral based (with only 3.7% transport based). However,

cars and other forms of transportion (trucks, airplanes, boats, etc.) are

responsible for large amounts of NOx being released into the atmosphere

( creating smog and ozone pollution ).

While some of their effects are similar, the large scale release of these

two componds represent two different major

enviornmental problems and should not be confused.

After SO2 and NO2 are released into the

atmosphere they are not particularuly acidic or soluble in H2O.

However they are converted

to H2SO4 and HNO3 in the atmosphere

(using cloud condensation nuclei as catalases1) which

are both acidic and soluble in H2O. The process by which this

occurs is :

(1)

(2)

the hydroperoxyl radical then produces more hydroxyl radicals via the reaction :

(3)

The sulfuric acid produced in equation (2) is then released from the atmosphere in rain water. A simlar

process occurs to produce HNO3 and rid it from the atmosphere. The

lifetime of SO2 is only a few days and as a result rainfall containing

high amounts of H2SO4 only occurs a few hundred miles

from the source of emission. This effect can be seen in a recent

pH map of the United States where the lowest pH readings are centered

around the NorthEast (the country's industral backbone). Another important fact

pertaining to this map is that rainfall is naturally acidic. Carbon dioxide found

in the atmosphere is dissolved into the water droplets existing in clouds and

effectly lowers the pH of rain to about 5.7 log units. Despite carbon dioxide's

role in lowering the pH of rainfall, large increases in the amounts

of carbon dioxide found in the

atmosphere are not expected to cause a large decrease in the pH of rainfall. ( For

instance, a doubling in CO2 concerntrations results in only about a

0.2 unit decrese in pH)1.

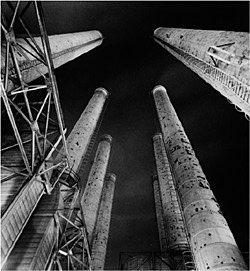

The SO2 released be power plants can by reduced by appoximately 90% through the use of

a scrubber or more offically known as flue gas desulfuriztion. This is achieved through the use of calcium carbonate.

(4)

(5)

In order to reduce the effects of acid rain, the EPA has recently

initiated an Acid Rain Program

aimed at "significantly reducing electric utilties emissions

of sulfur dioxide and nitrogen oxides".

The

Clean Air Act's primary goal is reduction of annual

SO2

emissions by 10 million tons below 1980 levels (0.9 million tons).

Legislation introduced by the EPA calls for a "two-phase tightening of

the restrictions placed on fossil fuel-fired power plants."

Meeting the new emission restrictions has forced companies to use existing

techonoloies to reduce the level of emissions.

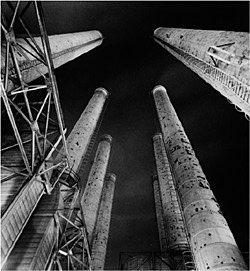

A large number of emission reducing processes are availiable such as

wet and dry flue gas desulfuriztion

,

dry acid gas scrubbing systems for solid

waste incineration

,

electrostatic precipitators

and

fabric filters

and are

currently being empolyed by companies like

General Electric.

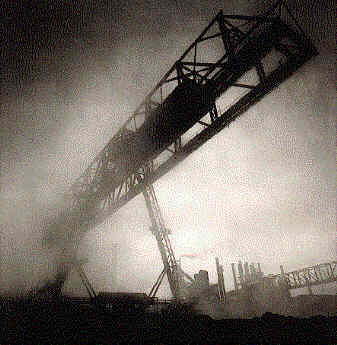

The effectiveness of these

processes can be easily seen by the almost 50% reduction of the total

national amount of sulfer dioxide

released from the 1980 emission level (about 40% below the EPA allowable

emissions for 1995).

Despite the large decrease in SO2 emissions by 1995, the annual

heat input from utilities remained constant (even increasing in some states) as

can be shown by examining figures2

2

and

3.

This shows that current techonolgies are able to cause

significant reduction of

sulfur dioxide emissions without having an addverse effect on industral output.

figure 2

figure 2

The EPA has devised an

Allowance Trading Plan

to help ease the cost of installing clean air

systems. Each year the allowable amount of emissions are are divided into credits and

given to companies where the emissions of each company is not to exceed thier number of

credits. Companies are allowed to sell their credits as they chose. By selling there credits

to a larger company, smaller companies are able to afford the costs of installation.

The volume of allowance trading shows that more and more companies are taking advantage

of the EPA's system and are updating their plants. Since the second phase of the EPA's plan will

increase the number of units involed from about 450 to 2000, this is a

positive indicator that the future goals (for the year 2000) will be able to

be met.

Other companies are using other approaches to help curve the cost of reduced emissions.

Their solution, which is by far the best long term solution to pollution, is to recycle their

waste products into other marketable goods.

Other companies are using other approaches to help curve the cost of reduced emissions.

Their solution, which is by far the best long term solution to pollution, is to recycle their

waste products into other marketable goods.

There have been some companies that have taken advantage of the cleaning of

the waste produced by coal-powered electric plants. The Tennessee Valley

Authority's Cumberland Power plant is one such example. During the production

of power, the sulfur gases produced are sent through electrostatic

precipitators, which remove the fly ash, and then continue through the flue gas

desulfurization scrubbers where the gas is sprayed with a scubber slurry that

absorbs the SO2. This SO2 laden acidic liquid is then neutralized by the

addition of crushed limestone which results in calcium sulfite. With a heavy

blast of air, the material is oxidized and forms calcium sulfate- more commonly

known as "gypsum." This Plant produced over a million tons of gypsum annually.

In the past, this product was shipped off to a disposal site where it was

buried at a cost to the company and could possibly harm the environment.

At the Cumberland Plant, they have signed several contracts with other

companies, SYNMAT and Temple Inland, for the purchase of the high quality

gypsum. These companies would then use the gypsum to produce wallboard,

cement additives, and for use in loosening soil for agricultural purposes.

The wallboard plant was built next to the power plant to minimize hauling

distances (reduce pollution from transport vehicles). Not only does this

process make more jobs available, but it also reduces environmental pollutants

while generating another source of income for the company. Still other companies such as

ReUse

use the collected sulfer to make soil feritzlers. This will pay for

the extra costs involved with the installation of the advanced technologies.

New techonologies are being developed to create more efficeint filtering systems.

Companies are developing methods using

activated coke/carbon

to help reduce toxic gas emissions (claims a 98% sulfur removal rate).

Other researchers3 report

that vast improvements in the reaction rate of calcuim with SO2 are possible by reducing the

diameter of the calcium particles used in scubbers (thus increase their effectivness).

NOx gasses have had recent solutions discovered. Ballard Power systems has

designed a fuel cell that runs on external fuel. This process converts

hydrogen and oxygen into water and produces electricity. (diagram)

The only drawback to implementing this system is the cost. The fuel cells

cost roughly ten times the amount of the internal combustion engine, running

the price from near $3000 to $30,000. The fuel cells are hoped to be in cars

within the next decade.